UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

SCHEDULE 14A

Proxy Statement Pursuant to Section 14(a) of

the Securities Exchange Act of 1934

| Filed by the Registrant x | |

| Filed by a Party other than the Registrant ¨ | |

| Check the appropriate box: | |

| ¨ | Preliminary Proxy Statement |

| ¨ | Confidential, for Use of the Commission Only (as permitted by Rule 14a-6(e)(2)) |

| ¨ | Definitive Proxy Statement |

| ¨ | Definitive Additional Materials |

| x | Soliciting Material under §240.14a-12 |

| United States Steel Corporation | |

| (Name of Registrant as Specified In Its Charter) | |

| (Name of Person(s) Filing Proxy Statement, if other than the Registrant) | |

| Payment of Filing Fee (Check the appropriate box): | |

| x | No fee required. |

| ¨ | Fee paid previously with preliminary materials. |

| ¨ | Fee computed on table in exhibit required by Item 25(b) per Exchange Act Rules 14a-6(i)(1) and 0-11 |

The following investor presentation was or will be presented by Nippon Steel Corporation to its investors on December 18, 2023.

TYO : 5401 OTC : NPSCY(ADR) Dec 18 , 2023 Acquisition of U.S.Steel

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 2 1. Overview 2. Rationale 3. Strengths of U.S.Steel 4. Appendix ( Strengths of Nippon Steel) 5. Appendix (Data of U.S.Steel ) Agenda

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 3 Moving Forward Together as the "Best Steelmaker with World - Leading Capabilities" Combines world - leading technologies and manufacturing capabilities to better serve customers worldwide “Best Steelmaker with World - Leading Capabilities” Delivering Best for All Ⓡ Brings together two storied companies with rich histories of industry - leading innovation Drives the global steel industry towards decarbonization and a sustainable world with a shared commitment to decarbonize by 2050 U.S.Steel to retain its brand name and headquarters in Pittsburgh, PA

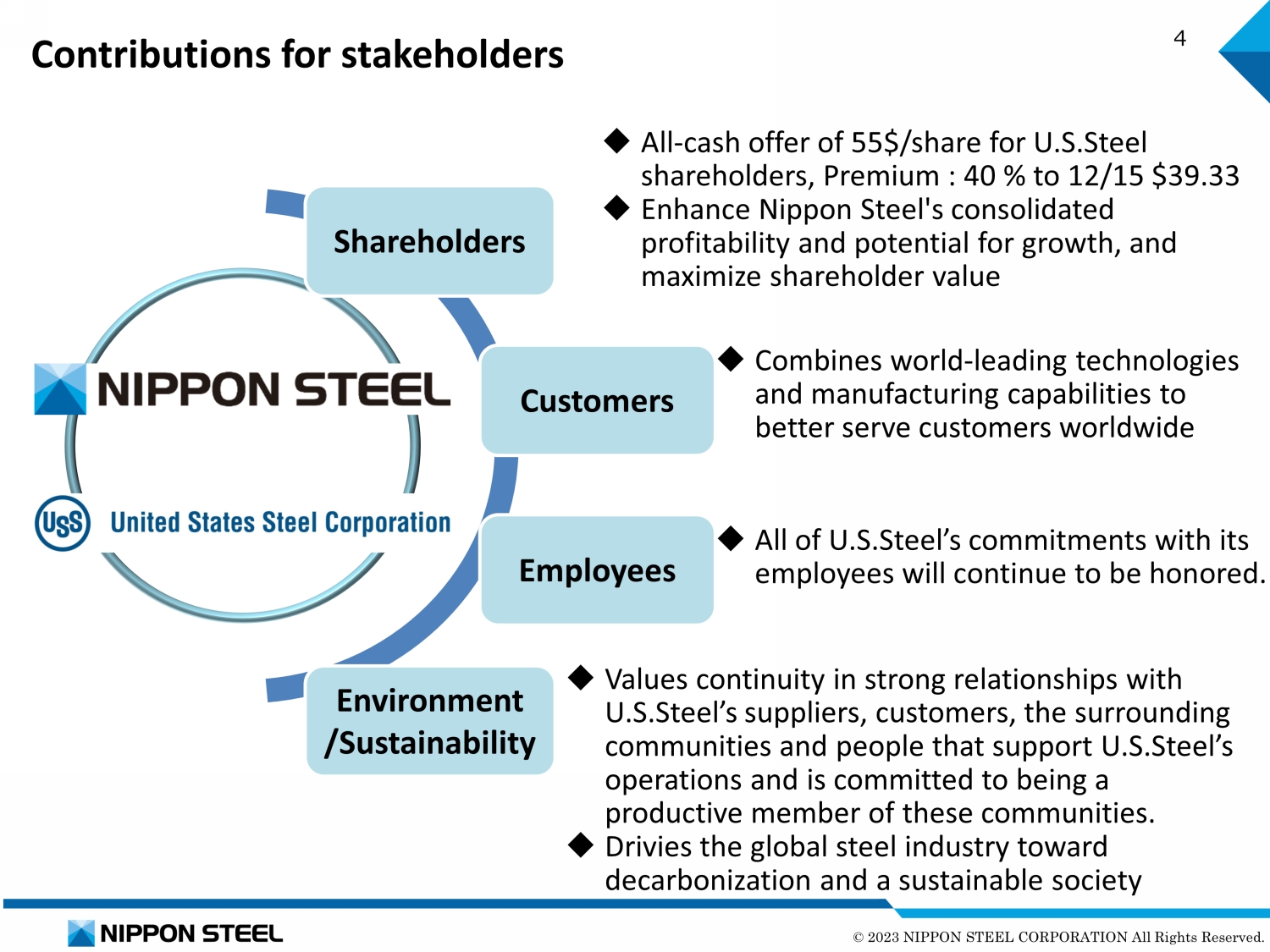

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 4 Contributions for stakeholders Customers Employees Environment /Sustainability Shareholders All - cash offer of 55$/share for U.S.Steel shareholders, Premium : 40 % to 12/15 $39.33 Enhance Nippon Steel's consolidated profitability and potential for growth, and maximize shareholder value Combine s world - leading technologies and manufacturing capabilities to better serve customers worldwide All of U.S.Steel ’ s commitments with its employees will continue to be honored . Values continuity in strong relationships with U.S.Steel’s suppliers, customers, the surrounding communities and people that support U.S.Steel’s operations and is committed to being a productive member of these communities. Drivi es the global steel industry toward decarbonization and a sustainable society

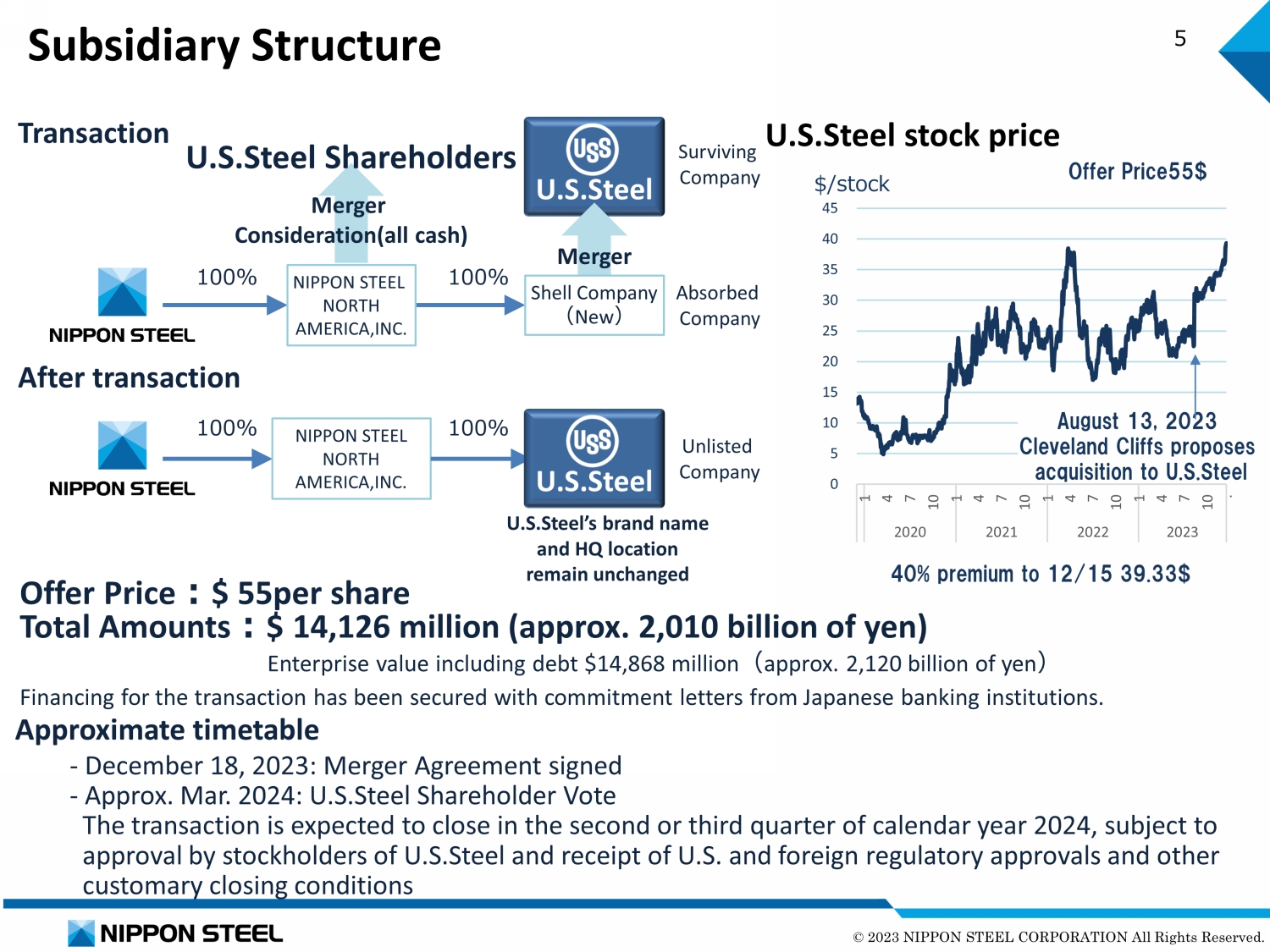

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 5 Subsidiary Structure - December 18, 2023: Merger Agreement signed - Approx. Mar. 2024: U.S.Steel Shareholder Vote The transaction is expected to close in the second or third quarter of calendar year 2024, subject to approval by stockholders of U.S.Steel and receipt of U.S. and foreign regulatory approvals and other customary closing conditions 0 5 10 15 20 25 30 35 40 45 1 4 7 10 1 4 7 10 1 4 7 10 1 4 7 10 . 2020 2021 2022 2023 $/stock U.S.Steel stock price Offer Price55$ Offer Price : $ 55per share Total Amounts : $ 14,126 mil lion (approx. 2,010 billion of yen ) Enterprise value including debt $14,868 million ( approx. 2,120 billion of yen ) Financing for the transaction has been secured with commitment letters from Japanese banking institutions. Approximate timetable 40% premium to 12/15 39.33$ August 13, 2023 Cleveland Cliffs proposes acquisition to U.S.Steel 100% 100% U.S.Steel S urviving C ompany A bsorbed C ompany Shell Company ( New ) M erger Consideration(all cash) Unlisted C ompany Merger NIPPON STEEL NORTH AMERICA,INC. 100% 100% U.S.Steel After transaction U.S.Steel Shareholders NIPPON STEEL NORTH AMERICA,INC. U.S.Steel’s brand name and HQ location remain unchanged Transaction

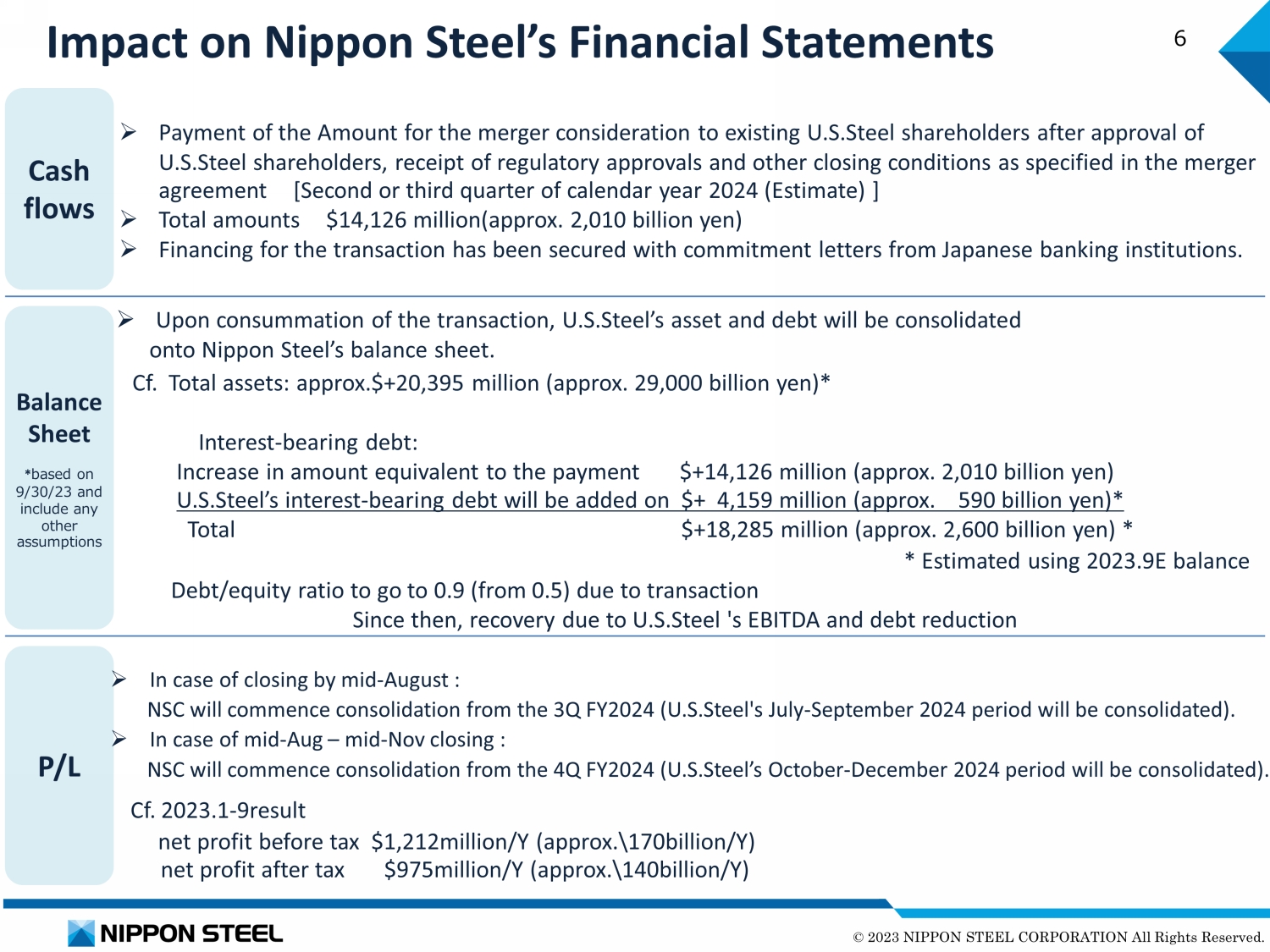

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 6 Impact on Nippon Steel’s Financial Statements Cf. 2023.1 - 9result net profit before tax $1,212million/Y (approx. \ 170billion/Y) net profit after tax $975million/Y (approx. \ 140billion/Y) Cash flows Balance Sheet * based on 9/30/23 and include any other assumptions P/L » Payment of the Amount for the merger consideration to existing U.S.Steel shareholders after approval of U.S.Steel shareholders, receipt of regulatory approvals and other closing conditions as specified in the merger agreement [Second or third quarter of calendar year 2024 (Estimate) ] » Total amounts $14,126 million(approx. 2,010 billion yen) » Financing for the transaction has been secured with commitment letters from Japanese banking institutions. » Upon consummation of the transaction, U.S.Steel’s asset and debt will be consolidated onto Nippon Steel’s balance sheet. Cf. Total assets: approx.$+20,395 million (approx. 29,000 billion yen)* Interest - bearing debt: Increase in amount equivalent to the payment $+14,126 million (approx. 2,010 billion yen) U.S.Steel’s interest - bearing debt will be added on $+ 4,159 million (approx. 590 billion yen)* Total $+18,285 million (approx. 2,600 billion yen) * * Estimated using 2023.9E balance Debt/equity ratio to go to 0.9 (from 0.5) due to transaction Since then, recovery due to U.S.Steel 's EBITDA and debt reduction » In case of closing by mid - August : NSC will commence consolidation from the 3Q FY2024 ( U.S.Steel's July - September 2024 period will be consolidated). » In case of mid - Aug – mid - Nov closing : NSC will commence consolidation from the 4Q FY2024 ( U.S.Steel’s October - December 2024 period will be consolidated).

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 7 1. Overview 2. Rationale 3. Strengths of U.S.Steel 4. Appendix ( Strengths of Nippon Steel) 5. Appendix (Data of U.S.Steel ) Agenda

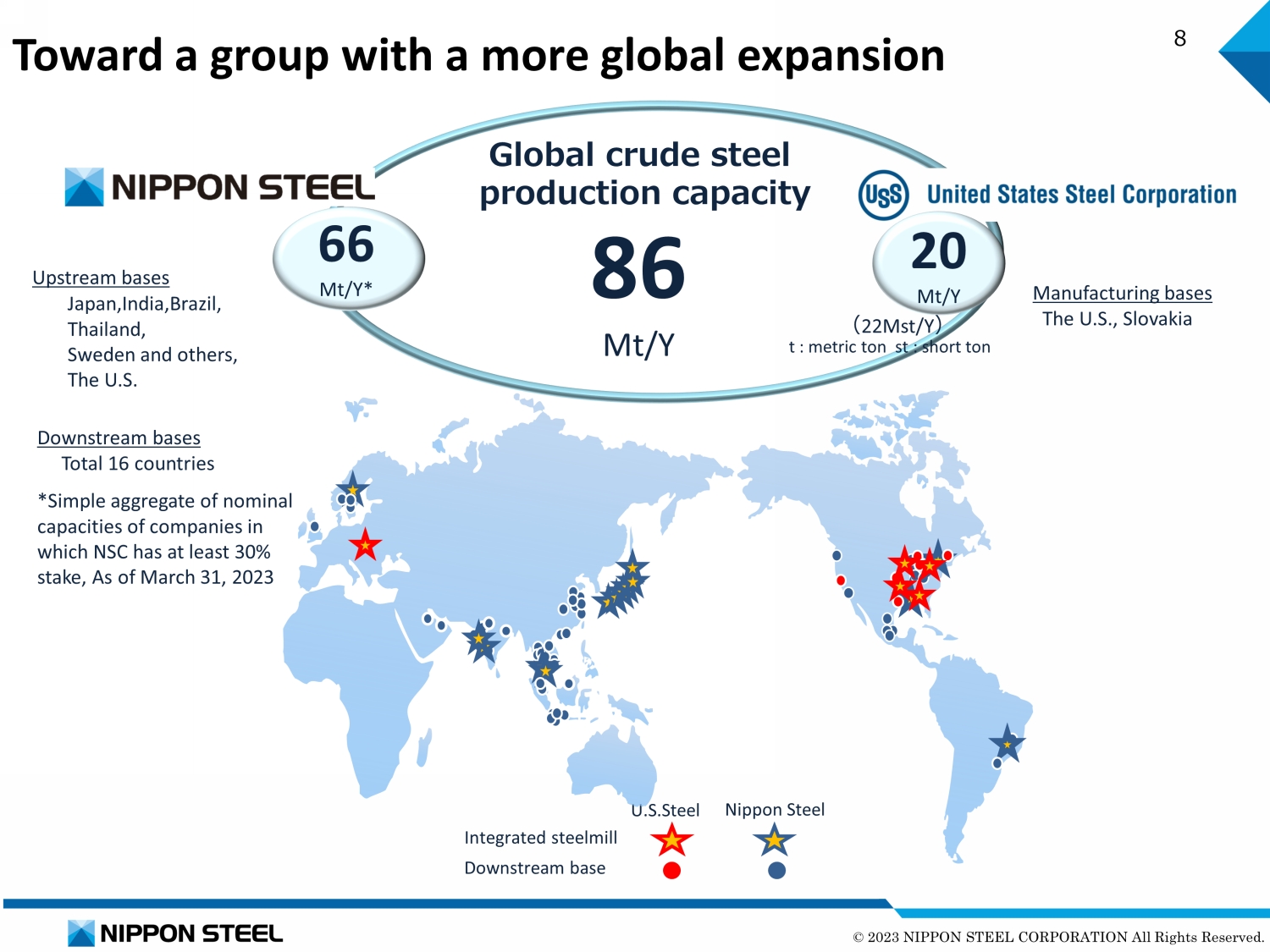

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 8 Downstream bases Total 16 countries *Simple aggregate of nominal capacities of companies in which NSC has at least 30% stake, As of March 31, 2023 Toward a group with a more global expansion 86 Mt/Y 20 Mt/Y 66 Mt/Y * D ownstream base I ntegrated steel mill U.S.Steel Nippon Steel G lobal crude steel production capacity Manufacturing bases The U.S., Slovakia Japan,India, Brazil, Thailand, Sweden and others, The U.S . Upstream bases * * * t : metric ton st : short ton ( 22Mst/Y )

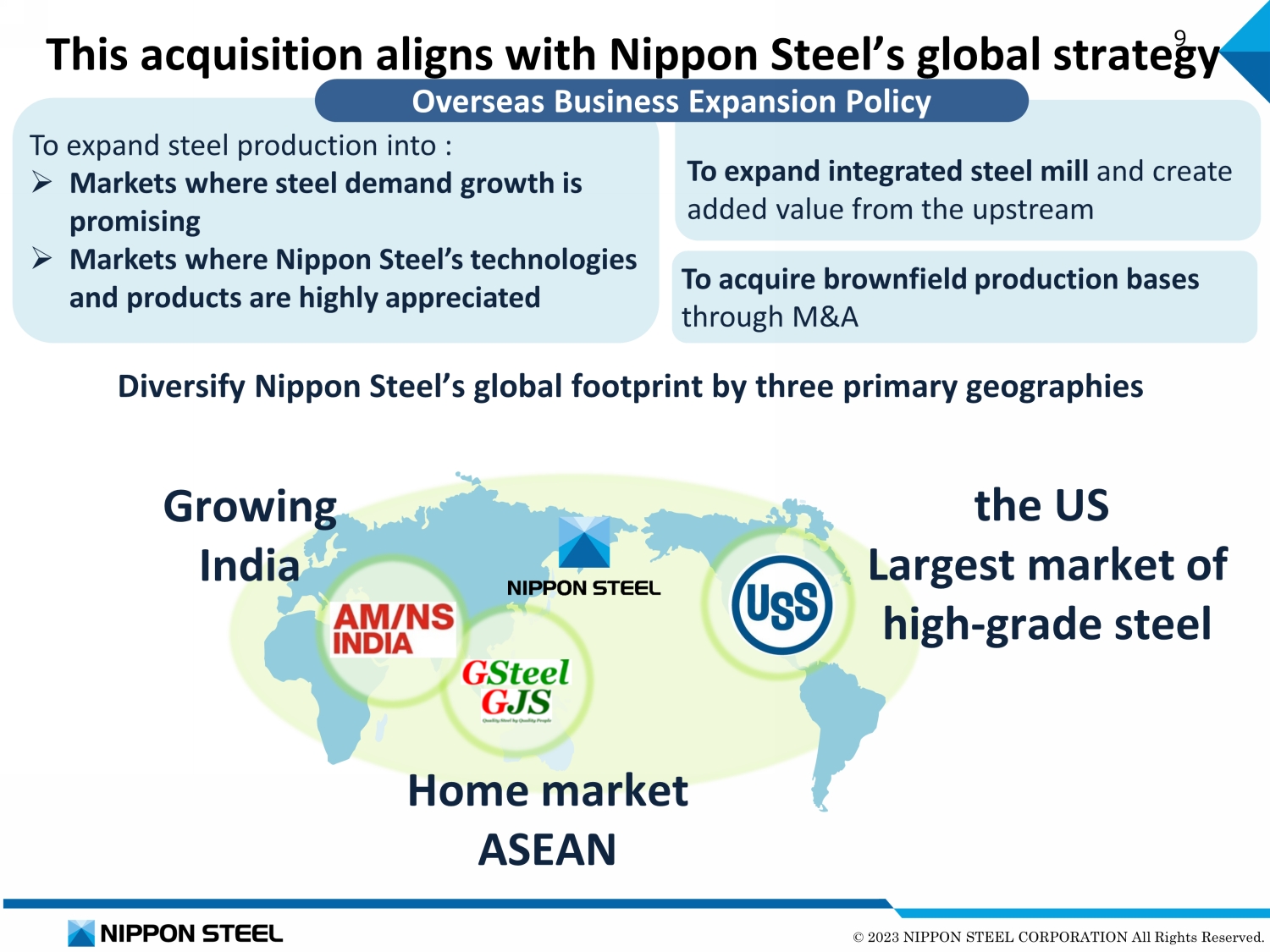

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 9 This acquisition aligns with Nippon Steel’s global strategy To expand steel production into : » Markets where steel demand growth is promising » Markets where Nippon Steel’s technologies and products are highly appreciated To acquire brownfield production bases through M&A To expand integrated steel mill and create added value from the upstream Diversify Nippon Steel’s global footprint by three primary geographies Overseas Business Expansion Policy Home market ASEAN Growing India the US Largest market of high - grade steel

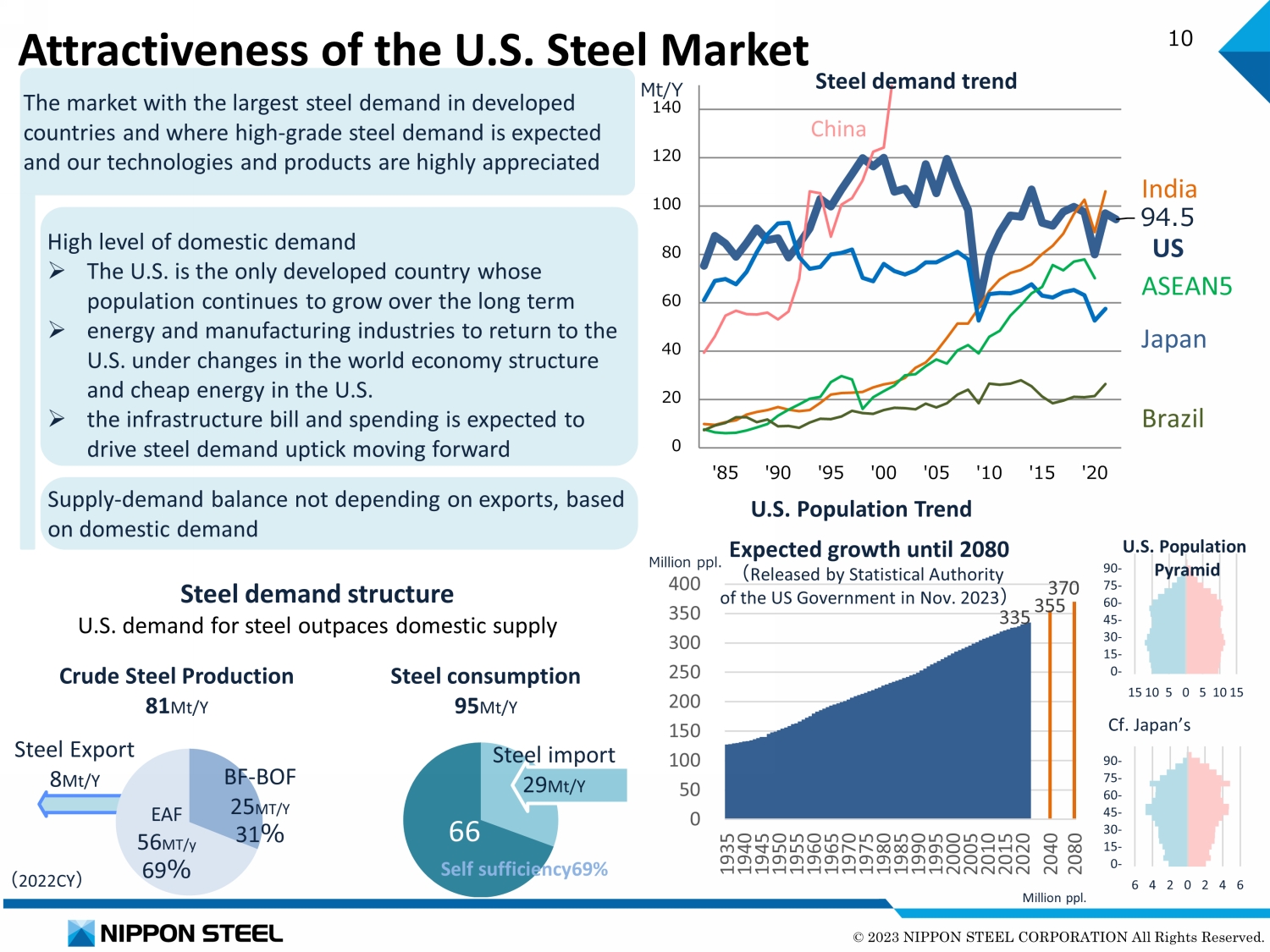

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 10 Attractiveness of the U.S. Steel Market Steel demand structure U.S. demand for steel outpaces domestic supply ( 2022CY ) EAF 56 MT/y 69 % BF - BOF 25 MT/Y 31 % 66 Steel import 29 Mt/Y Self sufficiency69% Steel Export 8 Mt/Y Steel consumption 95 Mt/Y Crude Steel Production 81 Mt/Y 335 355 370 0 50 100 150 200 250 300 350 400 1935 1940 1945 1950 1955 1960 1965 1970 1975 1980 1985 1990 1995 2000 2005 2010 2015 2020 2040 2080 Million ppl. 15 10 5 0 5 10 15 0- 15- 30- 45- 60- 75- 90- 6 4 2 0 2 4 6 0- 15- 30- 45- 60- 75- 90- U.S. Population Pyramid Cf. Japan’s Million ppl. U.S. Population Trend Expected growth until 2080 ( Released by Statistical Authority of the US Government in Nov. 2023 ) 94.5 0 20 40 60 80 100 120 140 '85 '90 '95 '00 '05 '10 '15 '20 Mt/Y China ASEAN5 India Japan Brazil US Steel demand trend The market with the largest steel demand in developed countries and where high - grade steel demand is expected and our technologies and products are highly appreciated High level of domestic demand » The U.S. is the only developed country whose population continues to grow over the long term » energy and manufacturing industries to return to the U.S. under changes in the world economy structure and cheap energy in the U.S. » the infrastructure bill and spending is expected to drive steel demand uptick moving forward Supply - demand balance not depending on exports, based on domestic demand

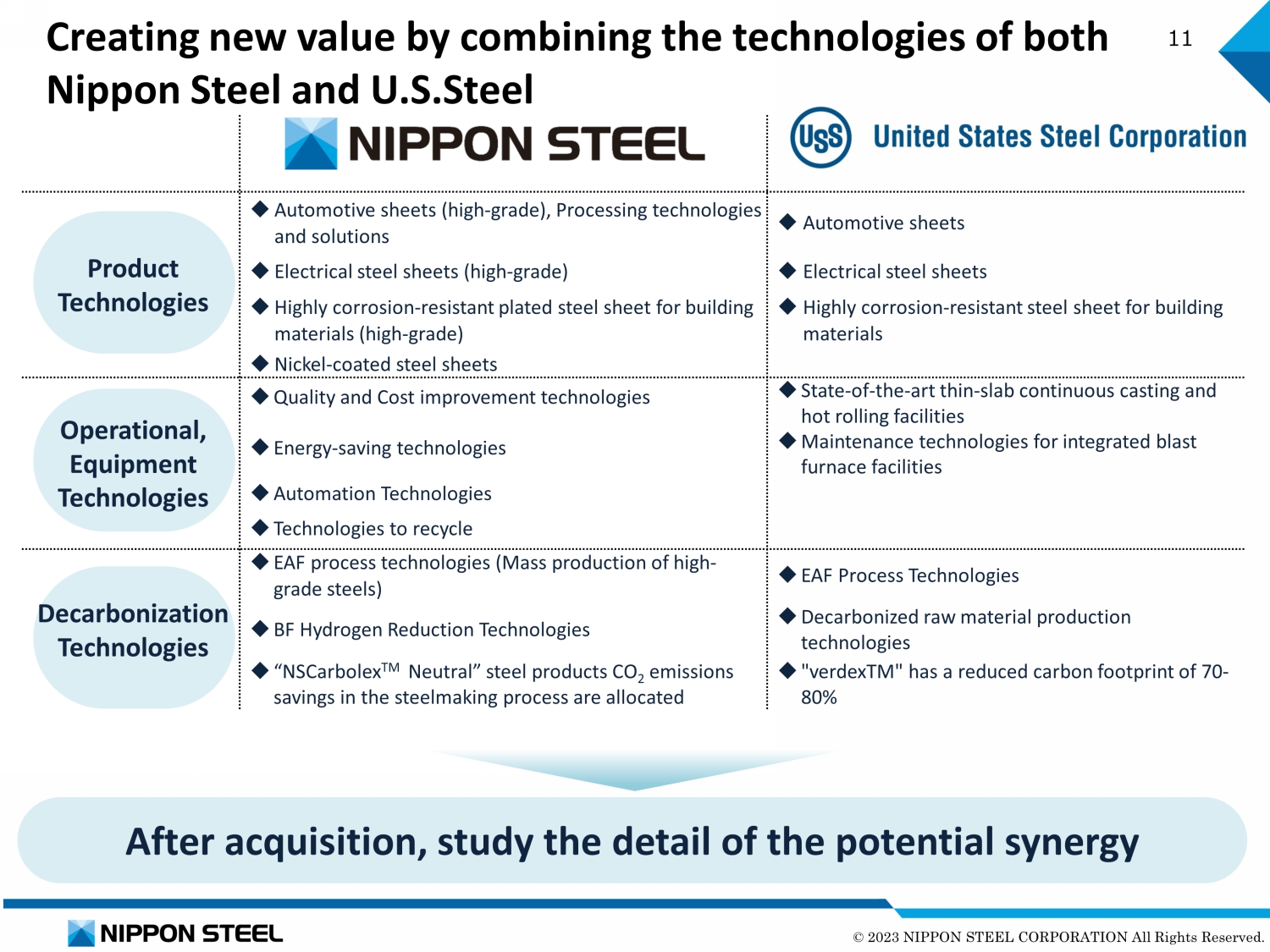

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 11 Creating new value by combining the techn ologies of both N ippon Steel and U.S.Steel After acquisition , study the detail of the potential synerg y P roduct T echnologies A uto motive sheets (high - grade), Processing technologies and solutions A uto motive sheets E lectrical steel sheets (high - grade) E lectrical steel sheets Highly corrosion - resistant plated steel sheet for building materials (high - grade) Highly corrosion - resistant steel sheet for building materials N ickel - coated steel sheets O perational, E quipment T echnologies Quality and Cost improvement technologies State - of - the - art thin - slab continuous casting and hot rolling facilities Maintenance technologies for integrated blast furnace facilities Energy - saving technologies Automation Technologies Technologies to recycle Decarbonization Technologies EAF process technologies (Mass production of high - grade steels) EAF Process Technologies BF Hydrogen Reduction Technologies Decarbonized raw material production technologies “ NSCarbolex TM Neutral” steel products CO 2 emissions savings in the steelmaking process are allocated " verdexTM " has a reduced carbon footprint of 70 - 80%

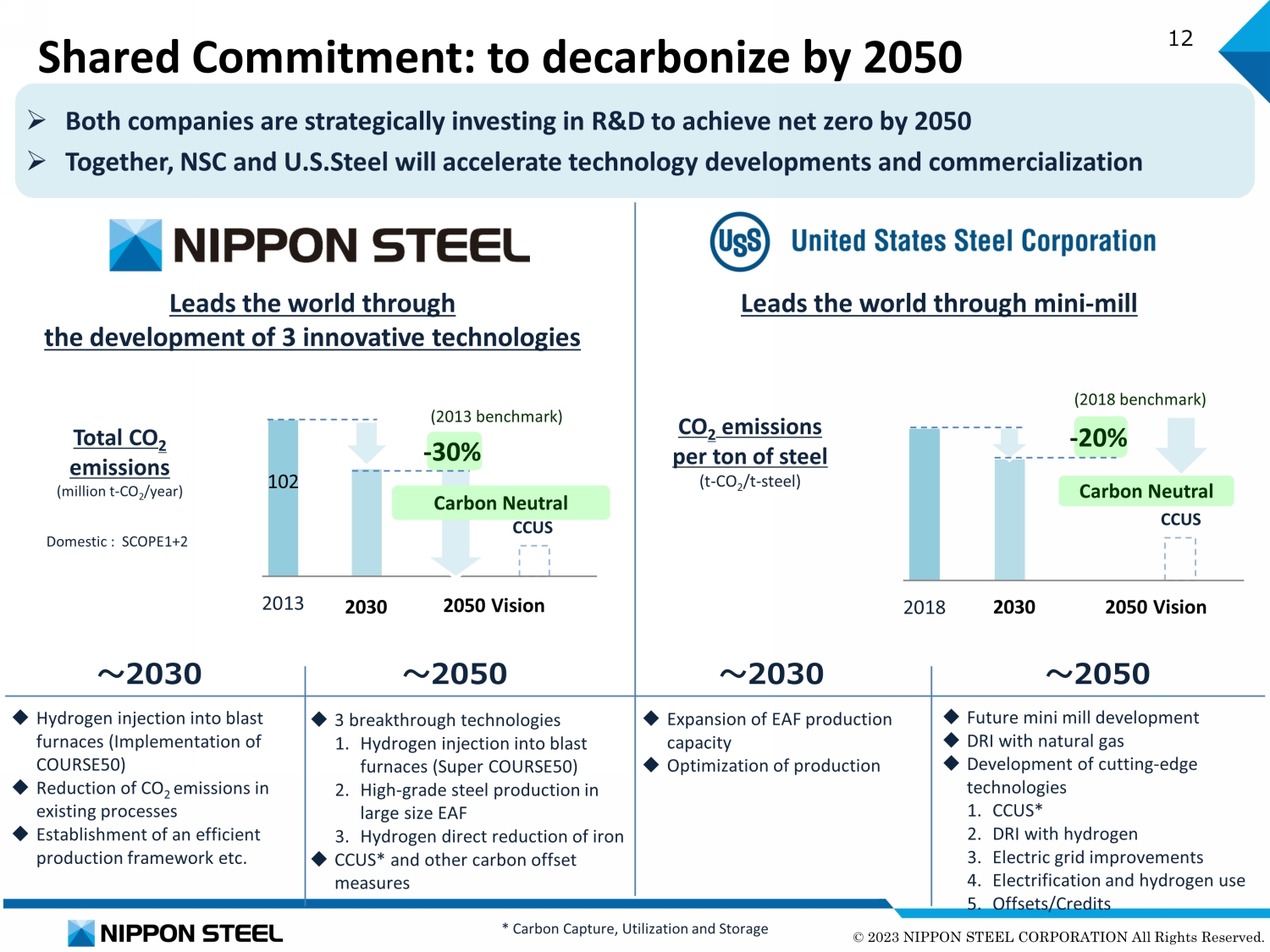

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 12 2018 CCUS - 20% Carbon Neutral 102 2013 CCUS - 30% Carbon Neutral Shared Commitment: to decarbonize by 2050 Hydrogen injection into blast furnaces (Implementation of COURSE50 ) Reduction of CO 2 emissions in existing processes Establishment of an efficient production framework etc. Domestic : SCOPE1+2 * Carbon Capture, Utilization and Storage 3 breakthrough technologies 1. Hydrogen injection into blast furnaces (Super COURSE50 ) 2. High - grade steel production in large size EAF 3. Hydrogen direct reduction of iron CCUS * and other carbon offset measures CO 2 emissions per ton of steel ( t - CO 2 /t - steel ) » Both companies are strategically investing in R&D to achieve net zero by 2050 » Together, NSC and U.S.Steel will accelerate technology developments and commercialization 2050 Vision 2030 (2013 benchmark) Expansion of EAF production capacity Optimization of production Future mini mill development DRI with natural gas Development of cutting - edge technologies 1. CCUS* 2. DRI with hydrogen 3. Electric grid improvements 4. Electrification and hydrogen use 5. Offsets/Credits 2030 2050 Vision (2018 benchmark) Leads the world through the development of 3 innovative technologies Total CO 2 emissions (million t - CO 2 /year) Leads the world through mini - mill ~ 2030 ~ 2050 ~ 2030 ~ 2050

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 13 1. Overview 2. Rationale 3. Strengths of U.S.Steel 4. Appendix ( Strengths of Nippon Steel) 5. Appendix (Data of U.S.Steel ) Agenda

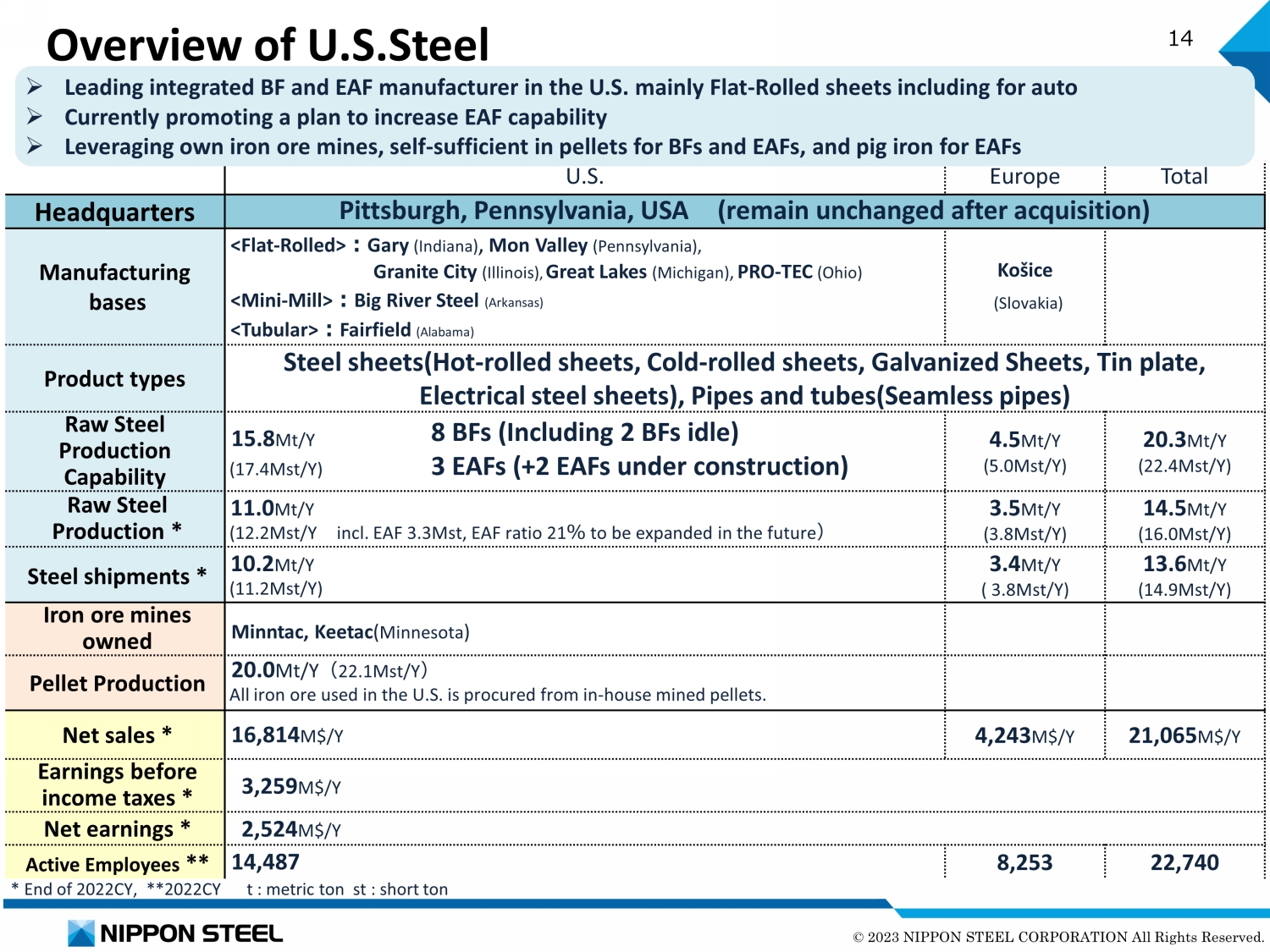

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 14 Overview of U.S.Steel U.S. Europe Total Headquarters Pittsburgh, Pennsylvania, USA (remain unchanged after acquisition) Manufacturing bases <Flat - Rolled> : Gary (Indiana ) , Mon Valley (Pennsylvania) , Granite City (Illinois) , Great Lakes (Michigan) , PRO - TEC (Ohio) <Mini - Mill> : Big River Steel (Arkansas) <Tubular> : Fairfield (Alabama) Košice ( Slovakia ) Product types Steel sheets ( Hot - rolled sheets , Cold - rolled sheet s, Galvanized Sheets, Tin plate, Electrical steel sheets ), Pipes and tubes (Seamless pipes) Raw Steel Production Capability 15.8 Mt/Y (17.4Mst/Y) 4.5 Mt/Y (5.0Mst/Y) 20.3 M t /Y (22.4 M st /Y ) Raw Steel Production * 11.0 M t /Y (12.2 M st /Y incl. EAF 3.3Mst, EAF ratio 21 % to be expanded in the future ) 3.5 M t /Y (3.8 M st /Y ) 14.5 M t /Y (16.0 M st /Y ) Steel shipments * 10.2 M t /Y (11.2 M st /Y ) 3.4 M t /Y ( 3.8 M st /Y ) 13.6 M t /Y (14.9 M st /Y ) Iron ore mines owned Minntac , Keetac ( Minnesota ) Pellet Production 20.0 M t /Y ( 22.1 M st /Y ) All iron ore used in the U.S. is procured from in - house mined pellets . Net sales * 16,814 M$/Y 4,243 M$/Y 21,065 M$/Y Earnings before income taxes * 3,259 M$/Y Net earnings * 2,524 M$/Y Active Employees ** 14,487 8,253 22,740 * End of 2022CY, **2022CY t : metric ton st : short ton » Leading integrated BF and EAF manufacturer in the U.S. mainly Flat - Rolled sheets including for auto » Currently promoting a plan to increase EAF capability » Leveraging own iron ore mines, self - sufficient in pellets for BFs and EAFs, and pig iron for EAFs 8 BFs (Including 2 BFs idle) 3 EAFs (+2 EAFs under construction)

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 15 Strengths of U.S.Steel Extensive U.S. Client base s Well - established history Brand value Excellent Management and employees Strong relationship with unions Good retention ratio Low cost i ron ore mines with abundant reserves Excellent financial structure D/E Ratio < 0.1 ( Net interest - bearing debt / Shareholders' equity ) Sufficient retirement benefit reserves Well - developed, customer - oriented R&D system and bases Munhall, Pennsylvania Houston, Texas Troy, Michigan, etc. Manufacturing C apital Social and R elation ship C apital H uman C apital I ntellectual C apital F inancial Capital N atural C apital Robust facilities organically combining iron ore mines, BFs , and EAFs Company brand name will remain unchanged after acquisition

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 16 Strengths of U.S.Steel - Strategic Investments On - time and on - budget, investments focused on expanding the competitive advantages from the raw material process to the finished product process are in progress. In addition to DR - grade pellets supplied to EAF, BF - grade pellets can also be produced Produced pellets can also be sold to third - party DRI or HBI producers Tons of Pig Iron Capability : 500 k/Y provide nearly 50% of Big River Steel's ore - based metallics needs DR - grade pellets facility Pig Iron Caste r N on - grain oriented electrical steel line G alvanize/Gal valume® line I ntegrated line from EAF to Steel Sheets $3,000 million $280 million $450 million $60 million $150 million Keetac Mine Gary Works Big River Big River 2 $650 million/Y $60 million/Y $140 million/Y $30 million/Y Construction started in 2022, Production start in 2024 Construction started in 2022, Shipment started in 4Q.2022 Construction started in 2022, Production started in Oct. 2023 Investing Expected Run - rate EBITDA * Tons of EAF Capability : 3 M/Y Installing state - of - the - art Endless Casting & Rolling Line Tons of Finishing Capability : 200 k/Y Meeting the growing electric vehicle demand Tons of Finishing Capability : 325 k/Y Manufactures Galvalume@ steel for exposed building panels and hot - dipped galvanizing steel for appliance and construction Construction started in 2021, Production start in 2024 Construction started in 2022, Production start in 2024 *Average assumed EBITDA if the current environment continues

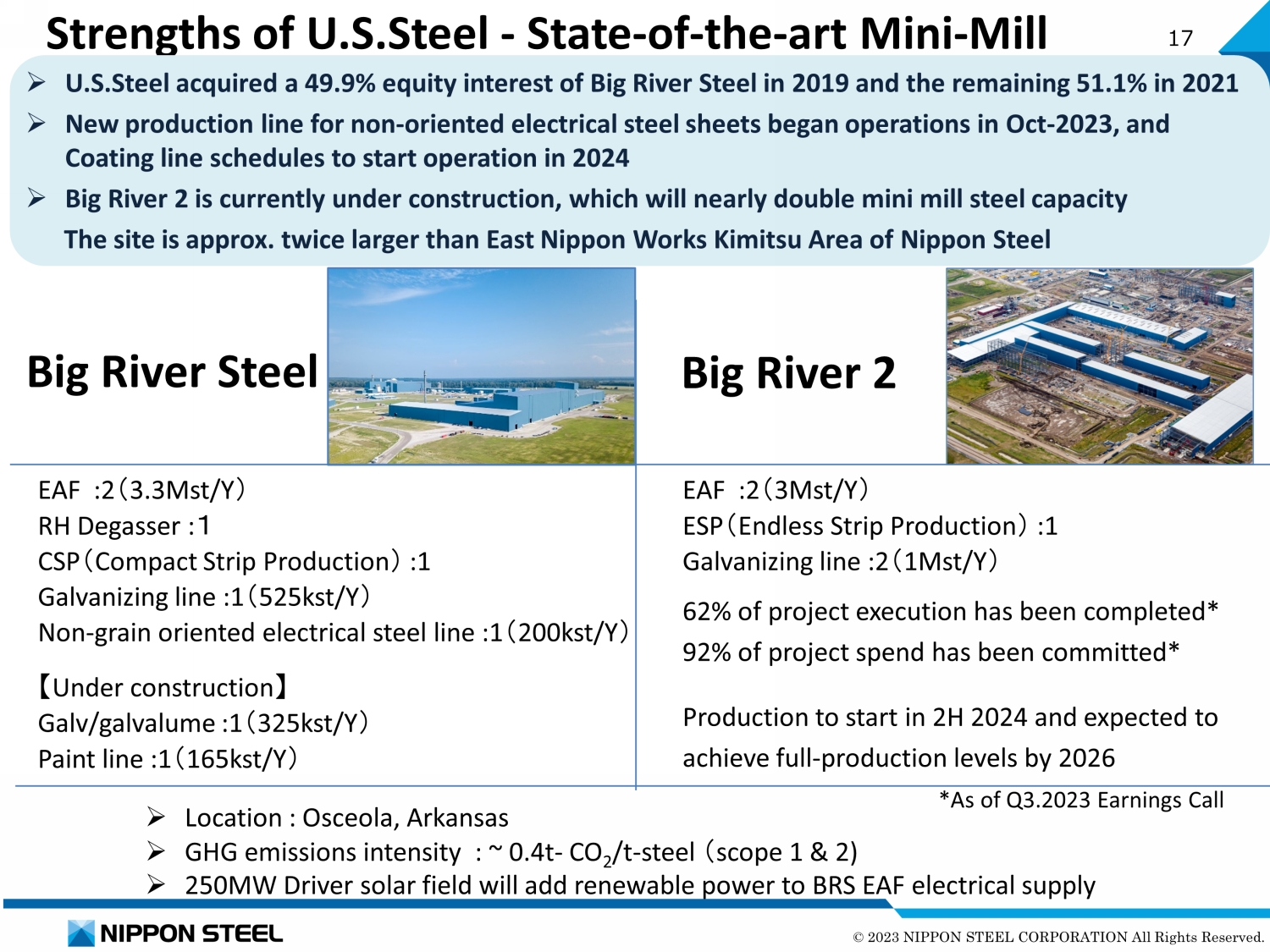

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 17 Strengths of U.S.Steel - State - of - the - art Mini - Mill » U.S.Steel acquired a 49.9% equity interest of Big River Steel in 2019 and the remaining 51.1% in 2021 » New production line for non - oriented electrical steel sheets began operations in Oct - 2023, and Coating line schedules to start operation in 2024 » Big River 2 is currently under construction, which will nearly double mini mill steel capacity The site is approx. twice larger than East Nippon Works Kimitsu Area of Nippon Steel Big River Steel Big River 2 EAF :2 ( 3.3Mst/Y ) RH Degasser : 1 CSP ( Compact Strip Production ) :1 Galvanizing line :1 ( 525kst/Y ) Non - grain oriented electrical steel line :1 ( 200kst/Y ) 【 Under construction 】 Galv /galvalume :1 ( 325kst/Y ) Paint line :1 ( 165kst/Y ) EAF :2 ( 3Mst/Y ) ESP ( Endless Strip Production ) :1 Galvanizing line :2 ( 1Mst/Y ) 62% of project execution has been completed* 92% of project spend has been committed* Production to start in 2H 2024 and expected to achieve full - production levels by 2026 *As of Q3.2023 Earnings Call » Location : Osceola , Arkansas » GHG emissions intensity : ~ 0.4t - CO 2 /t - steel ( scope 1 & 2) » 250MW Driver solar field will add renewable power to BRS EAF electrical supply

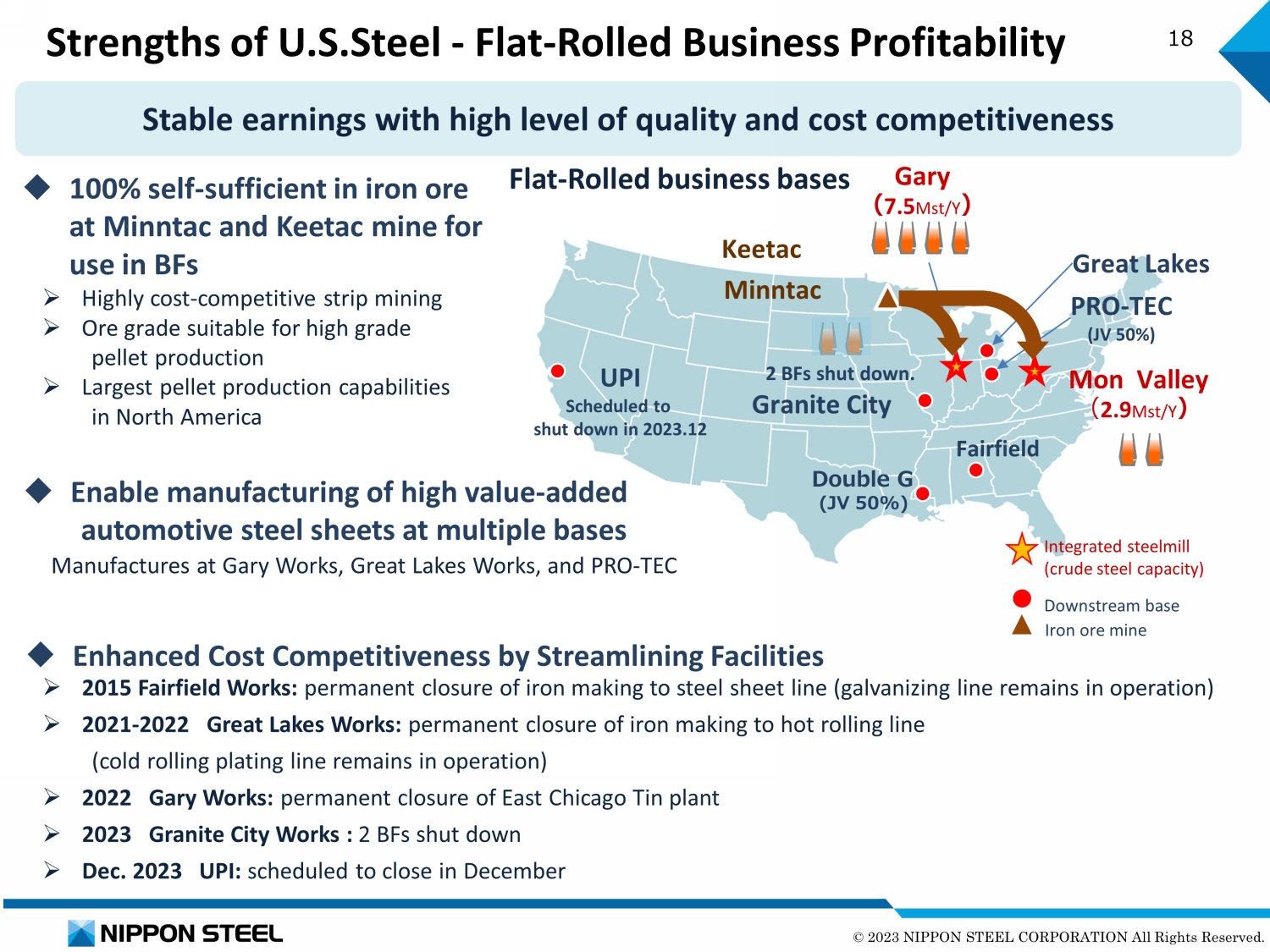

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 18 Gary ( 7.5 Mst/Y ) Mon Valley ( 2.9 Mst/Y ) Granite City Great Lakes PRO - TEC (JV 50%) UPI Scheduled to shut down in 2023.12 Keetac Minntac 2 BFs shut down . Fairfield Strengths of U.S.Steel - Flat - Rolled Business Profitability » 2015 Fairfield Works: permanent closure of iron making to steel sheet line (galvanizing line remains in operation) » 2021 - 2022 Great Lakes Works: permanent closure of iron making to hot rolling line (cold rolling plating line remains in operation) » 2022 Gary Works: permanent closure of East Chicago Tin plant » 2023 Granite City Works : 2 BFs shut down » Dec. 2023 UPI: scheduled to close in December 100% self - sufficient in iron ore at Minntac and Keetac mine for use in BFs Enhance d Cost Competitiveness by Streamlining Facilities Enable manufacturing of high value - added automotive steel sheets at multiple bases Manufactures at Gary Works, Great Lakes Works, and PRO - TEC I ntegrated steel mill (crude steel capacity) Downstream base Iron ore mine Stable earnings with high level of quality and cost competitiveness Flat - Rolled business bases » Highly cost - competitive strip mining » Ore grade suitable for high grade pellet production » Largest pellet production capabilities in North America Double G (JV 50%)

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 19 1. Overview 2. Rationale 3. Strengths of U.S.Steel 4. Appendix ( Strengths of Nippon Steel) 5. Appendix (Data of U.S.Steel ) Agenda

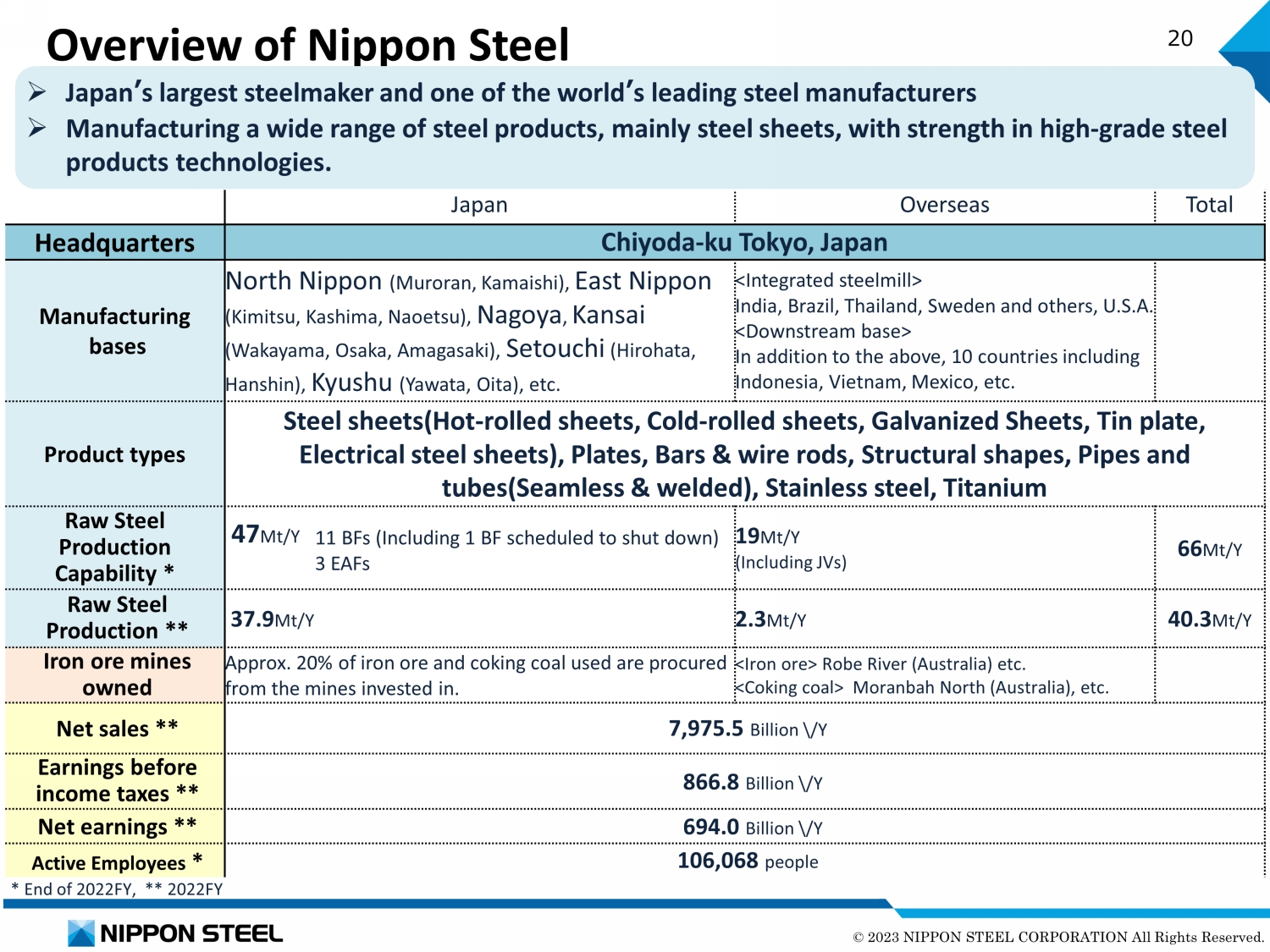

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 20 Overview of Nippon Steel Japan Overseas Total Headquarters Chiyoda - ku Tokyo, Japan Manufacturing bases North Nippon ( Muroran , Kamaishi ), East Nippon ( Kimitsu , Kashima, Naoetsu ), Nagoya , Kansai (Wakayama, Osaka, Amagasaki), Setouchi ( Hirohata , Hanshin), Kyushu (Yawata, Oita), etc. <Integrated steelmill > India, Brazil, Thailand, Sweden and others, U.S.A. <Downstream base> In addition to the above, 10 countries including Indonesia, Vietnam, Mexico, etc. Product types Steel sheets ( Hot - rolled sheets , Cold - rolled sheet s, Galvanized Sheets, Tin plate, Electrical steel sheets ), Plates, Bars & wire rods, Structural shapes, Pipes and tubes (Seamless & welded), Stainless steel, Titanium Raw Steel Production Capability * 47 Mt/Y 19 Mt/Y (Including JVs) 66 M t /Y Raw Steel Production ** 37.9 M t /Y 2.3 M t /Y 40.3 M t /Y Iron ore mines owned Approx. 20% of iron ore and coking coal used are procured from the mines invested in. < Iron ore > Ro be River (Australia) etc. < Coking coal > Moranbah North (Australia), etc. Net sales ** 7,975.5 Billion \ /Y Earnings before income taxes ** 866.8 Billion \ /Y Net earnings ** 694.0 Billion \ /Y Active Employees * 106,068 people * End of 2022FY, ** 2022FY » Japan ’ s largest steelmaker and one of the world ’ s leading steel manufacturers » Manufacturing a wide range of steel products, mainly steel sheets, with strength in high - grade steel products technologies. 11 BFs (Including 1 BF scheduled to shut down) 3 EAFs

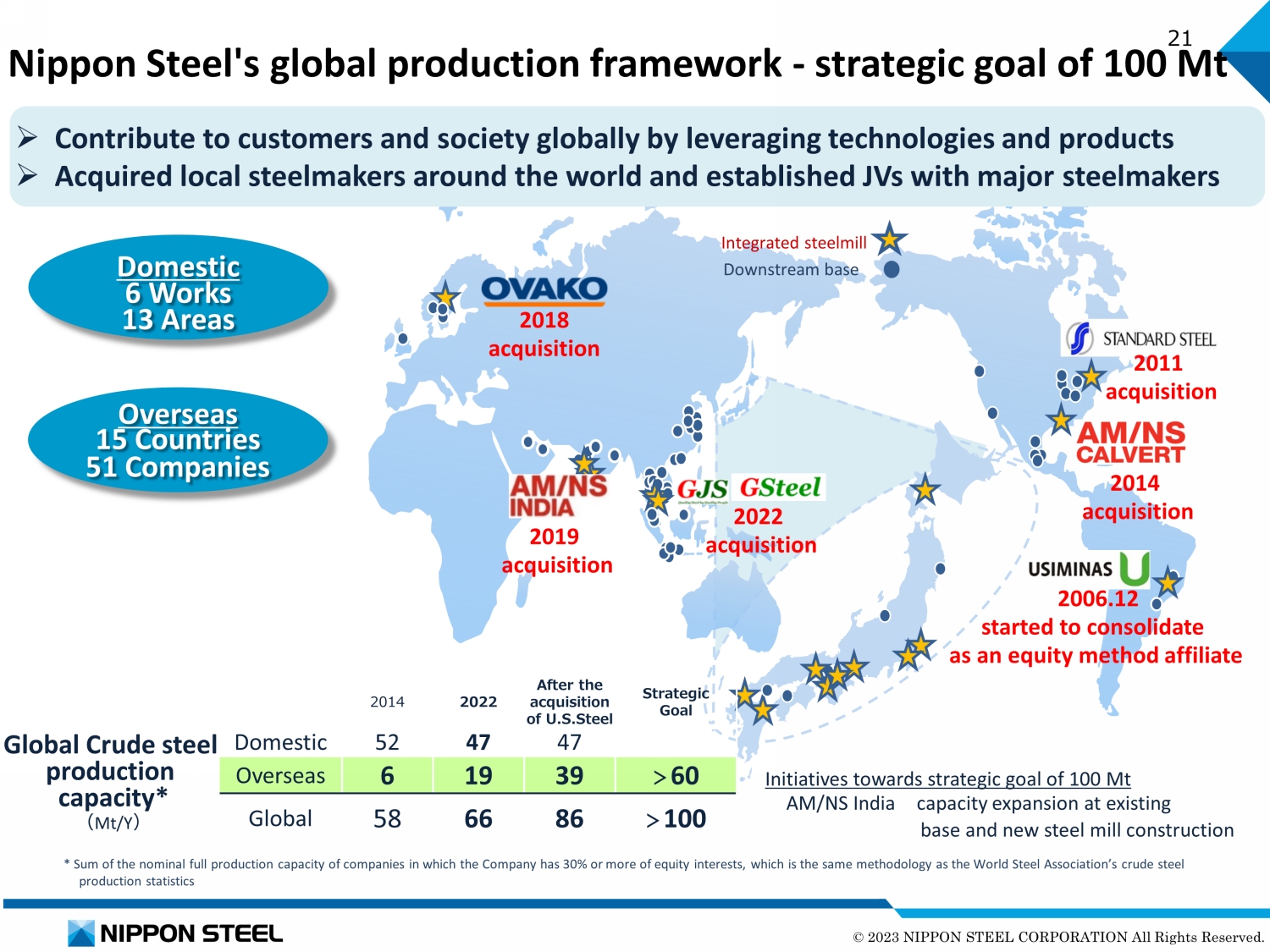

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 21 * * * 2018 acquisition 2019 acquisition 2014 acquisition 2022 acquisition 2006.12 started to consolidate as an equity method affiliate 2011 acquisition Domestic 6 Works 13 Areas Overseas 15 Countries 51 Companies 2014 2022 After the acquisition of U.S.Steel Strategic Goal Domestic 52 47 47 Overseas 6 19 39 > 60 Global 58 66 86 > 100 Global Crude steel production capacity * ( Mt/Y ) » Contribute to customers and society globally by leveraging technologies and products » Acquired local steelmakers around the world and established JVs with major steelmakers * Sum of the nominal full production capacity of companies in which the Company has 30% or more of equity interests, which is t he same methodology as the World Steel Association’s crude steel production statistics Initiatives towards strategic goal of 100 Mt AM/NS India capacity expansion at existing base and new steel mill construction I ntegrated steel mill Downstream base Nippon Steel's global production framework - strategic goal of 100 Mt

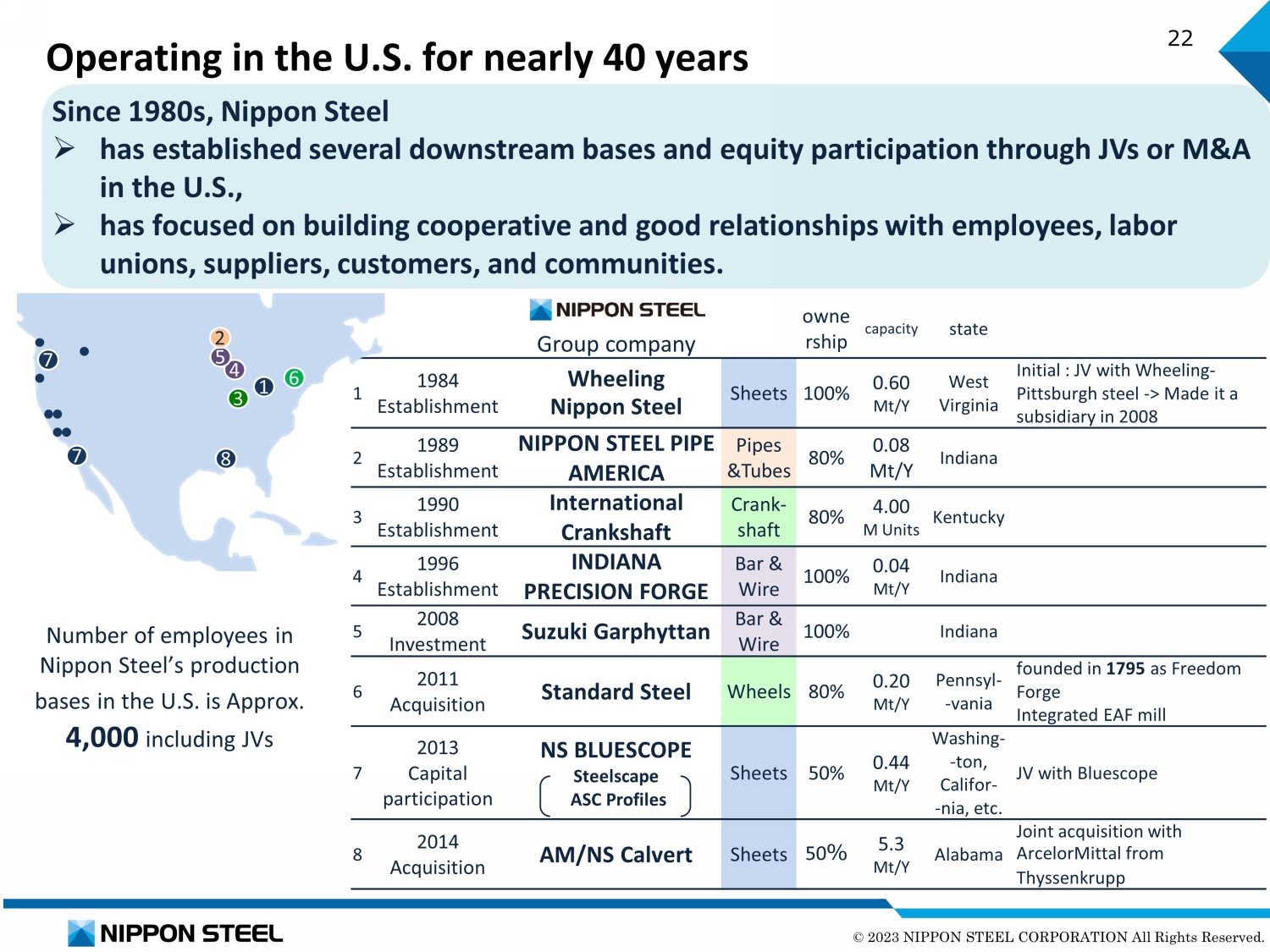

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 22 Operating in the U.S. for nearly 40 years Group company owne rship capacity state 1 1984 Establishment Wheeling Nippon Steel Sheets 100% 0.60 Mt/Y West Virginia Initial : JV with Wheeling - Pittsburgh steel - > Made it a subsidiary in 2008 2 1989 Establishment NIPPON STEEL PIPE AMERICA Pipes &Tubes 80% 0.08 Mt/Y Indiana 3 1990 E stablishment International Crankshaft Crank - shaft 80% 4.00 M Units Kentucky 4 1996 E stablishment INDIANA PRECISION FORGE Bar & Wire 100% 0.04 Mt/Y Indiana 5 2008 Investment Suzuki Garphyttan Bar & Wire 100% Indiana 6 2011 Acquisition Standard Steel Wheels 80% 0.20 Mt/Y Pennsyl - - vania founded in 1795 as Freedom Forge Integrated EAF mill 7 2013 Capital participation NS BLUESCOPE Steelscape ASC Profiles Sheets 50% 0.44 Mt/Y Washing - - ton, Califor - - nia , etc. JV with Bluescope 8 2014 Acquisition AM/NS Calvert Sheets 50 % 5.3 Mt/Y Alabama Joint acquisition with ArcelorMittal from Thyssenkrupp Since 1980s, Nippon Steel » has established several downstream bases and equity participation through JVs or M&A in the U.S., » has focused on building cooperative and good relationships with employees, labor unions, suppliers, customers, and communities. Number of employees in Nippon Steel’s production bases in the U.S. is Approx. 4,000 including JVs 7 4 7 6 8 5 3 1 2

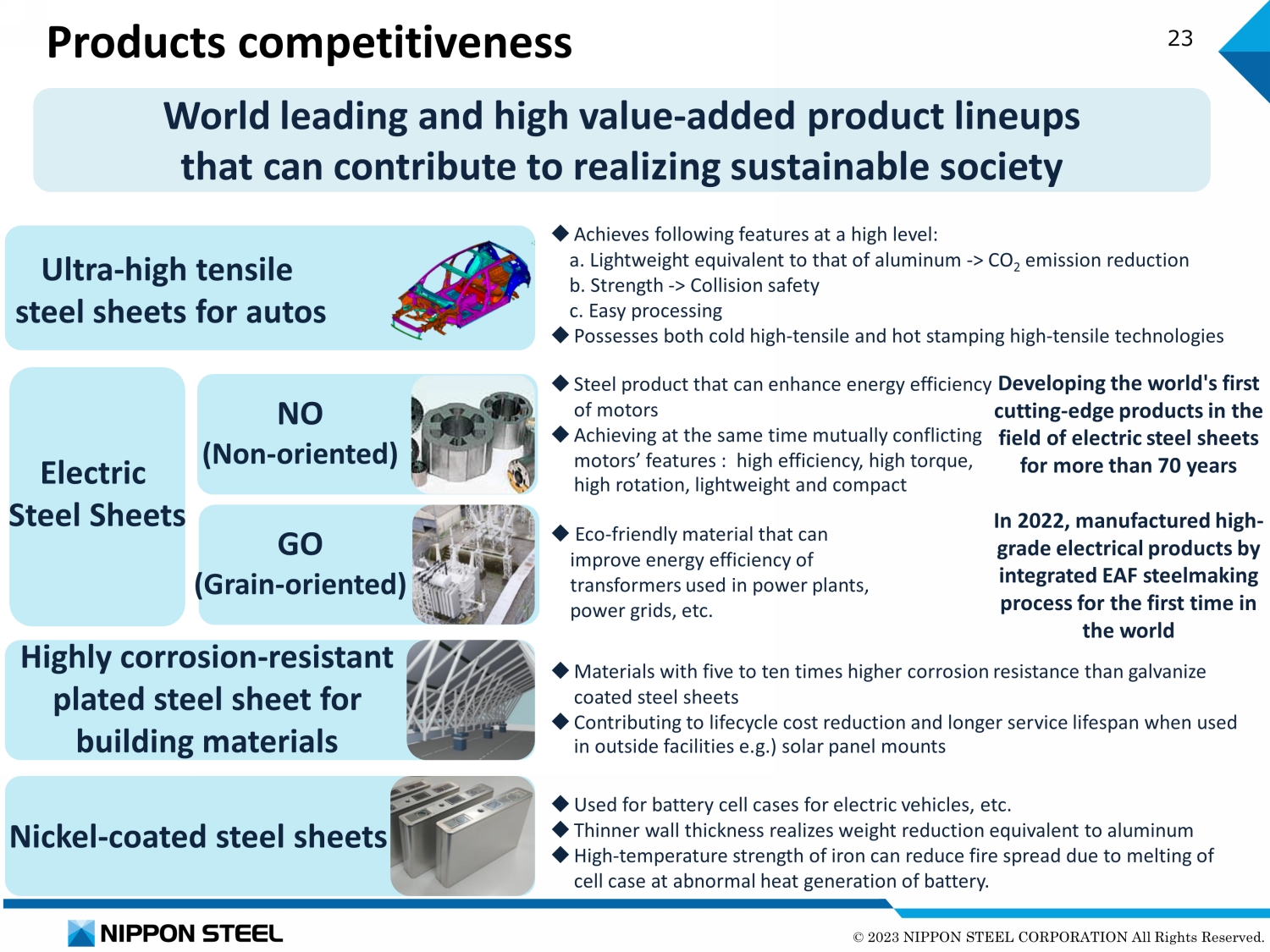

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 23 Products competitiveness World leading and high value - added product lineups that can contribute to realizing sustainable society Steel product that can enhance energy efficiency of motors Achieving at the same time mutually conflicting motors’ features : high efficiency, high torque, high rotation, lightweight and compact Eco - friendly material that can improve energy efficiency of transformers used in power plants, power grids, etc. Achieves following features at a high level: a. Lightweight equivalent to that of aluminum - > CO 2 emission reduction b. Strength - > Collision safety c. Easy processing Possesses both cold high - tensile and hot stamping high - tensile technologies Used for battery cell cases for electric vehicles, etc. Thinner wall thickness realizes weight reduction equivalent to aluminum High - temperature strength of iron can reduce fire spread due to melting of cell case at abnormal heat generation of battery. Materials with five to ten times higher corrosion resistance than galvanize coated steel sheets Contributing to lifecycle cost reduction and longer service lifespan when used in outside facilities e.g.) solar panel mounts NO (Non - oriented) Ultra - high tensile steel sheets for autos GO (Grain - oriented) Highly corrosion - resistant plated steel sheet for building materials Nickel - coated steel sheets Electric Steel Sheets Developing the world's first cutting - edge products in the field of electric steel sheets for more than 70 years In 2022, manufactured high - grade electrical products by integrated EAF steelmaking process for the first time in the world

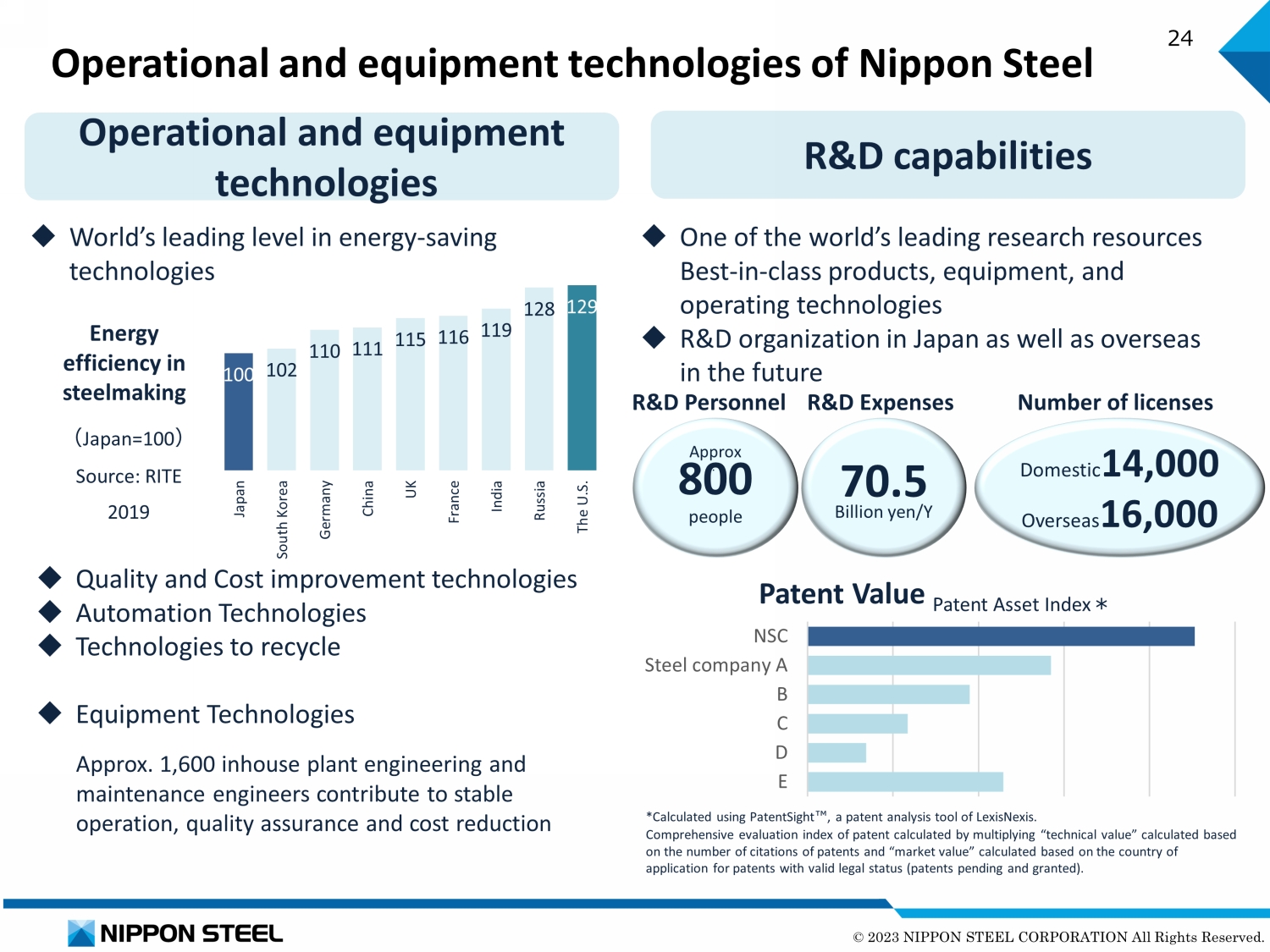

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 24 Operational and equipment technologies of Nippon Steel 100 102 110 111 115 116 119 128 129 Japan South Korea Germany China UK France India Russia The U.S. ( Japan=100 ) Source: RITE 2019 Patent Value Patent Asset Index * NSC Steel company A B C D E *Calculated using PatentSight æ , a patent analysis tool of LexisNexis. Comprehensive evaluation index of patent calculated by multiplying “technical value” calculated based on the number of citations of patents and “market value” calculated based on the country of application for patents with valid legal status (patents pending and granted). Operational and equipment technologies R&D capabilities One of the world’s leading research resources Best - in - class products, equipment, and operating technologies R&D organization in Japan as well as overseas in the future Energy efficiency in steelmaking Approx . 800 people 70.5 Billion yen/Y Domestic 14,000 O verseas 16,000 R&D Personnel R&D Expenses Number of licenses World ’s leading level in energy - saving technologies Quality and Cost improvement technologies Automation Technologies Technologies to recycle Equipment Technologies Approx. 1,600 inhouse plant engineering and maintenance engineers contribute to stable operation, quality assurance and cost reduction

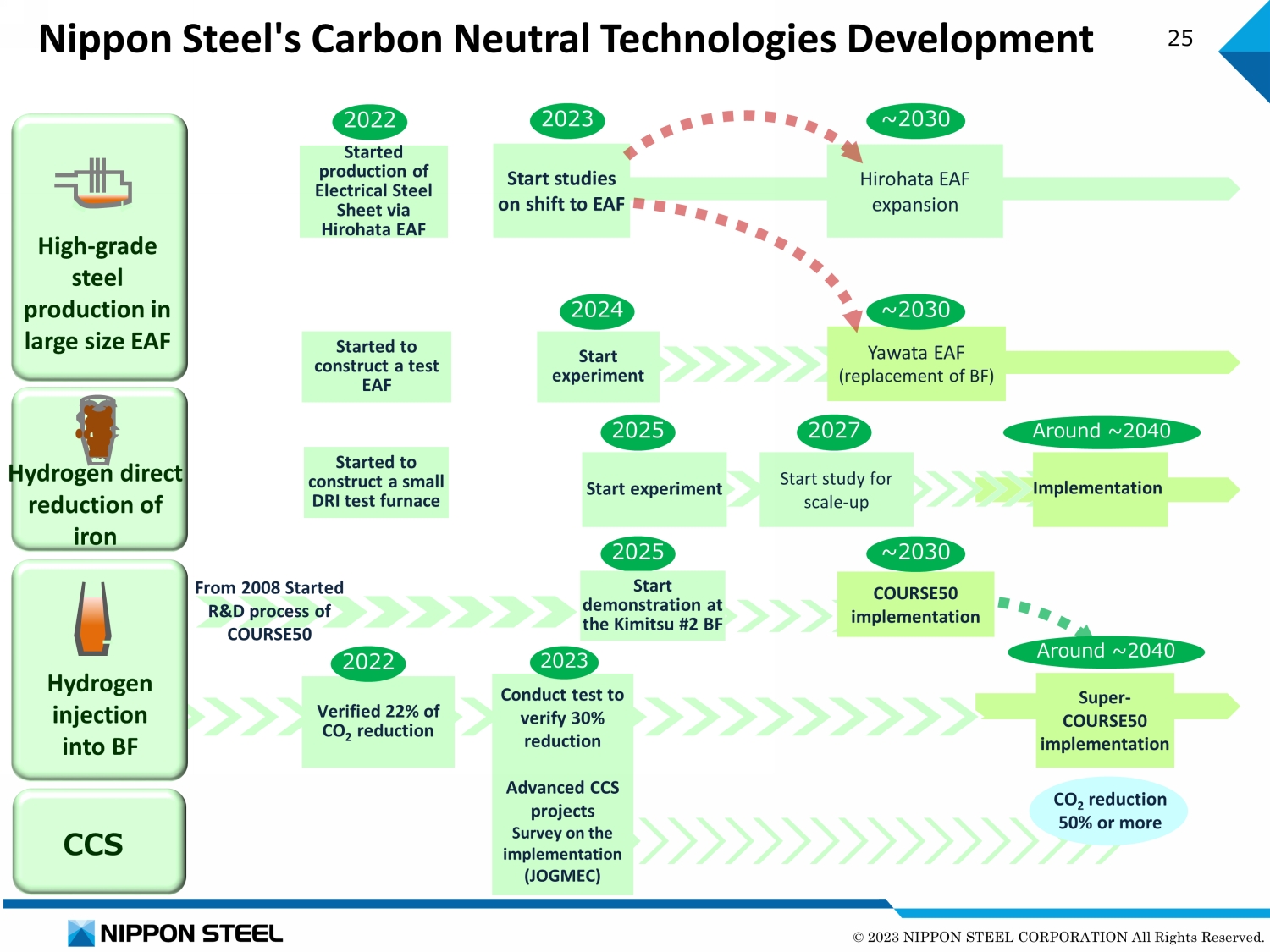

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 25 Around ~2040 Nippon Steel's Carbon Neutral Technologies Development 2022 2025 2027 Yawata EAF (replacement of BF) ~2030 ~2030 2023 Implementation 2024 Around ~2040 Conduct test to verify 30% reduction Advanced CCS projects Survey on the implementation ( JOGMEC ) Started production of Electrical Steel Sheet via Hirohata EAF High - grade steel production in large size EAF Hydrogen direct reduction of iron COURSE50 implementation ~2030 CCS 2025 From 2008 Started R&D process of COURSE50 CO 2 reduction 50% or more Hydrogen injection into BF Hirohata EAF expansion Start studies on shift to EAF Start experiment Start study for scale - up Start experiment Start demonstration at the Kimitsu #2 BF Super - COURSE50 implementation 2023 Verified 22% of CO 2 reduction Started to construct a test EAF Started to construct a small DRI test furnace 2022

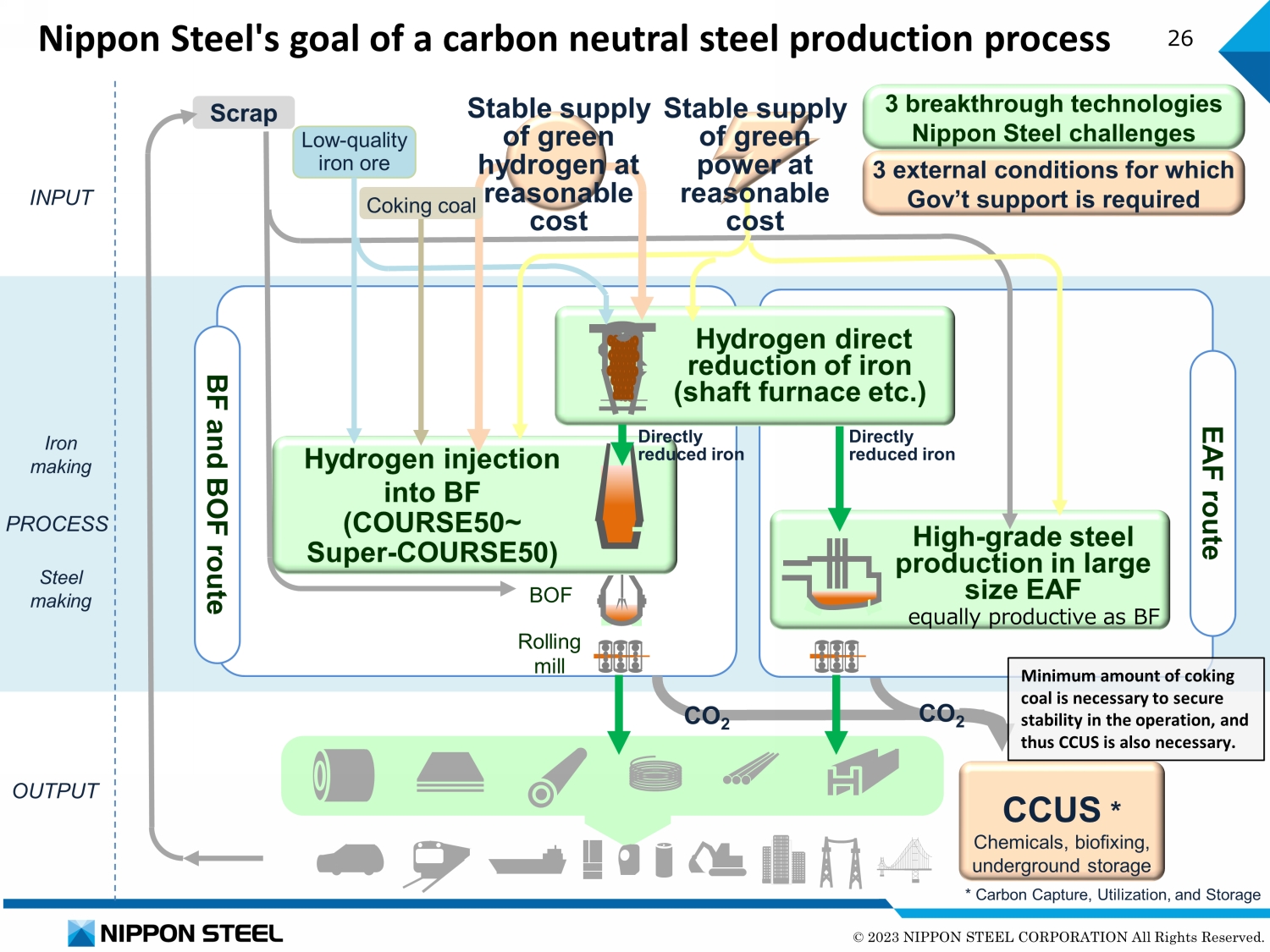

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 26 3 breakthrough technologies Nippon Steel challenges Nippon Steel's goal of a carbon neutral steel production process High - grade steel production in large size EAF Iron making Steel making Hydrogen injection into BF (COURSE50~ Super - COURSE50) OUTPUT PROCESS INPUT 3 external conditions for which Gov’t support is required BOF Rolling mill EAF route BF and BOF route Low - quality iron ore Coking coal Scrap Stable supply of green hydrogen at reasonable cost Stable supply of green power at reasonable cost CO 2 CO 2 Hydrogen direct reduction of iron (shaft furnace etc.) Directly reduced iron Directly reduced iron CCUS * Chemicals, biofixing, underground storage * Carbon Capture, Utilization, and Storage equally productive as BF Minimum amount of coking coal is necessary to secure stability in the operation, and thus CCUS is also necessary.

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 27 1. Overview 2. Rationale 3. Strengths of U.S.Steel 4. Appendix ( Strengths of Nippon Steel) 5. Appendix (Data of U.S.Steel) Agenda

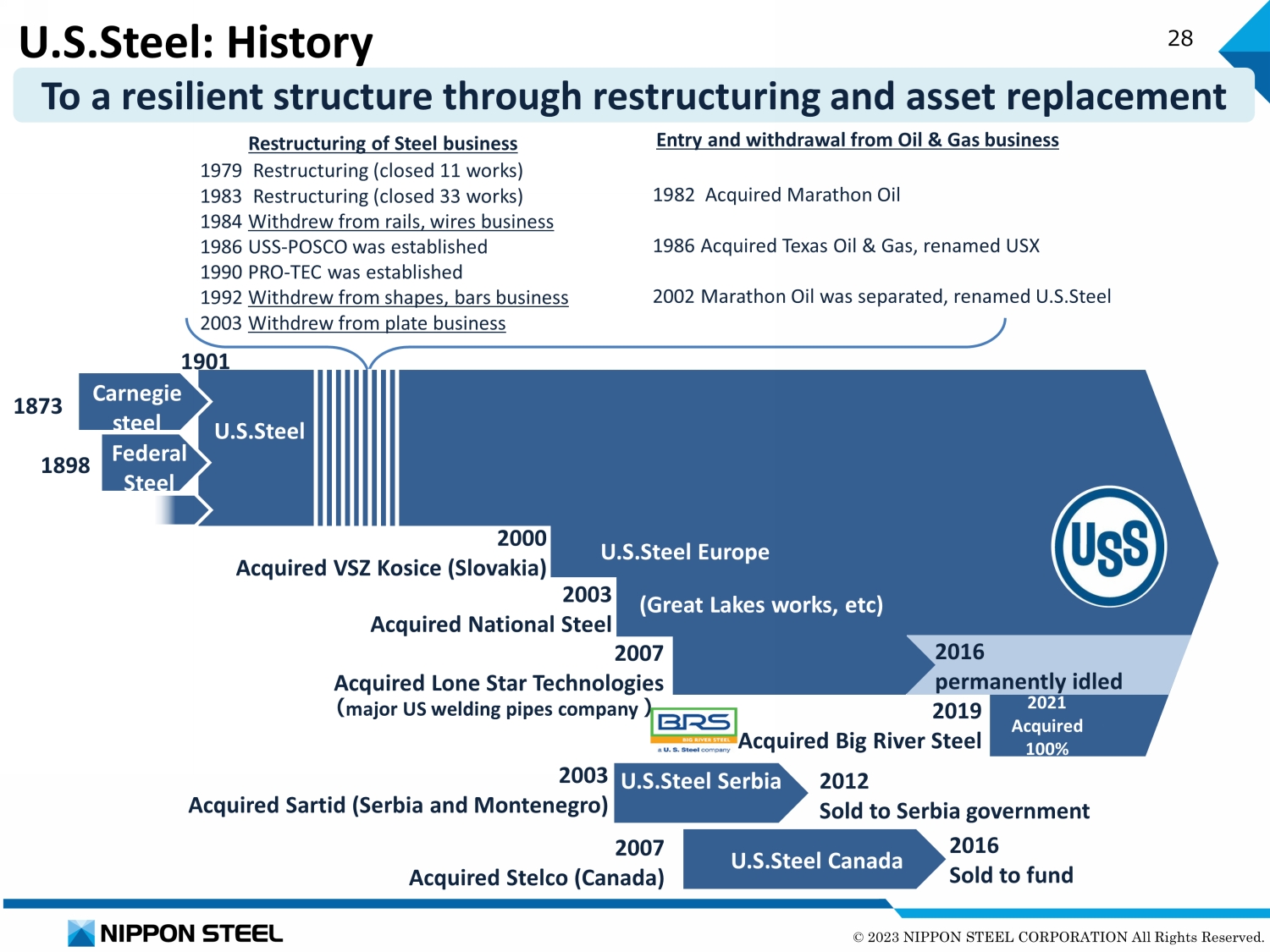

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 28 U.S.Steel : History 1979 R estructuring (closed 11 works) 1983 R estructuring (closed 33 works) 1984 Withdrew from rails, wires business 1986 U SS - POSCO was established 1990 PRO - TEC was established 1992 Withdrew from shapes, bars business 2003 Withdrew from plate business 1982 Acquired Marathon Oil 1986 Acquired Texas Oil & Gas , renamed USX 200 2 Marathon Oil was separated, renamed U.S.Steel Entry and withdrawal from Oil & Gas business R estructuring of Steel business 2003 Acquired Sartid (S erbia and Montenegro ) 2003 Acquired National Steel 2007 Acquired Stelco (Canada) 2012 Sold to Serbia government 2016 Sold to fund 2019 Acquired Big River Steel U.S.Steel U.S.Steel Canada U.S.Steel Serbia 2007 Acquired Lone Star Technologies ( major US welding pipes company ) 1873 1898 Carnegie steel Federal Steel 1901 U.S.Steel Europe (Great Lakes works, etc ) 2016 permanently idled 2021 Acquired 100% 2000 Acquired VSZ Kosice ( Slovakia ) To a r esilient s tructure through r estructuring and a sset r eplacement

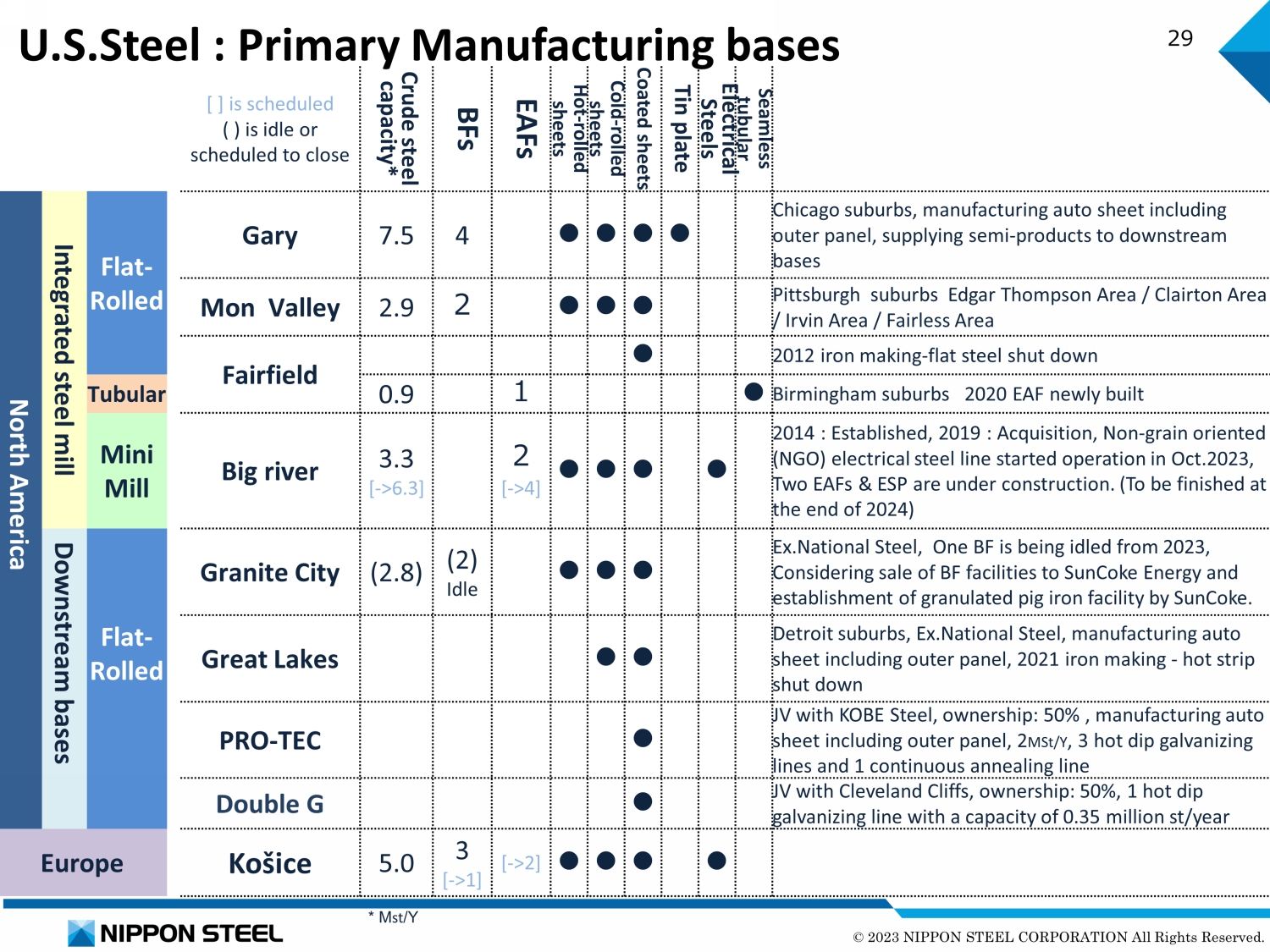

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 29 U.S.Steel : Primary Manufacturing bases [ ] is scheduled ( ) is idle or scheduled to close Crude steel capacity* BFs EAFs Hot - rolled sheets Cold - rolled sheets Coated sheets Tin plate Electrical Steel s Seamless tubular North America Integrated steel mill Flat - Rolled Gary 7.5 4 ● ● ● ● Chicago suburbs, manufacturing auto sheet including outer panel, supplying semi - products to downstream bases Mon Valley 2.9 2 ● ● ● Pittsburgh suburbs Edgar Thompson Area / Clairton Area / Irvin Area / Fairless Area Fairfield ● 2012 iron making - flat steel shut down Tubular 0.9 1 ● Birmingham suburbs 2020 EAF newly built Mini Mill Big river 3.3 [ - > 6.3] 2 [ - > 4] ● ● ● ● 2014 : Established, 2019 : Acquisition, N on - grain oriented (NGO) electrical steel line started operation in Oct.2023, Two EAFs & ESP are under construction. (To be finished at the end of 2024) Downstream bases Flat - Rolled Granite City (2.8) (2) Idle ● ● ● Ex.National Steel, One BF is being idled from 2023, Considering sale of BF facilities to SunCoke Energy and establishment of granulated pig iron facility by SunCoke . Great Lakes ● ● Detroit suburbs, Ex.National Steel, manufacturing auto sheet including outer panel, 2021 iron making - hot strip shut down PRO - TEC ● JV with KOBE Steel, ownership: 50% , manufacturing auto sheet including outer panel, 2 MSt/Y , 3 hot dip galvanizing lines and 1 continuous annealing line Double G ● JV with Cleveland Cliffs , ownership : 50%, 1 hot dip galvanizing line with a capacity of 0.35 million st/year Europe Košice 5.0 3 [ - > 1] [ - > 2] ● ● ● ● * M st /Y

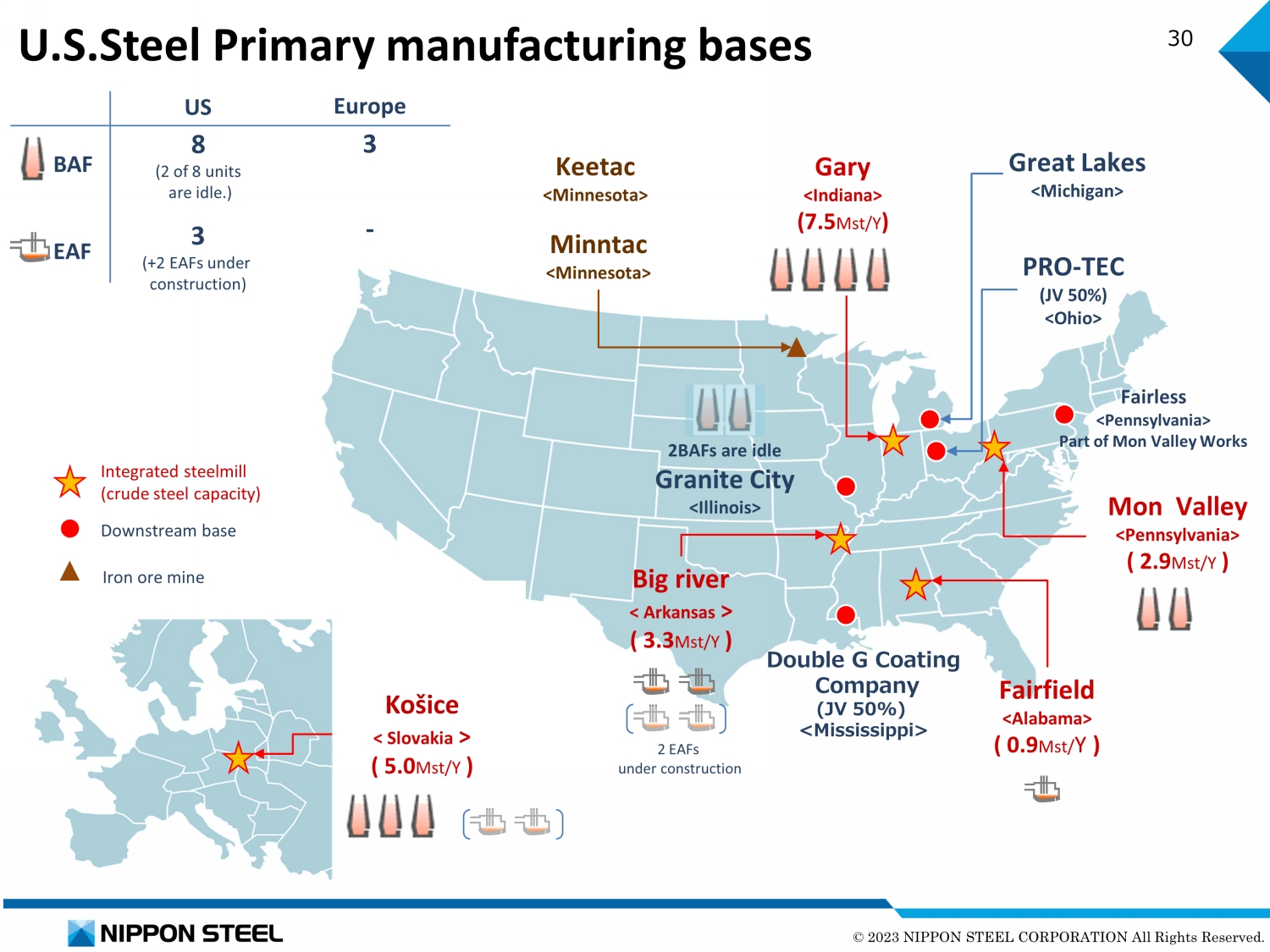

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 30 U.S.Steel Primary manufacturing bases Gary <Indiana> (7.5 Mst/Y ) Mon Valley <Pennsylvania> ( 2.9 Mst/Y ) 2BAFs are idle Granite City <Illinois> Fairfield <Alabama> ( 0.9 Mst/ Y ) Big river < Arkansas > ( 3.3 Mst/Y ) Great Lakes <Michigan> PRO - TEC (JV 50%) <Ohio> Keetac <Minnesota> Minntac <Minnesota> Fairless <Pennsylvania> Part of Mon Valley Works Košice < Slovakia > ( 5.0 Mst/Y ) I ntegrated steel mill (crude steel capacity) Downstream base Iron ore mine 2 EAF s under construction BAF EAF 8 ( 2 of 8 units are idle. ) 3 3 (+ 2 EAF s under c onstruction ) - US Europe Double G Coating Company (JV 50%) < Mississippi >

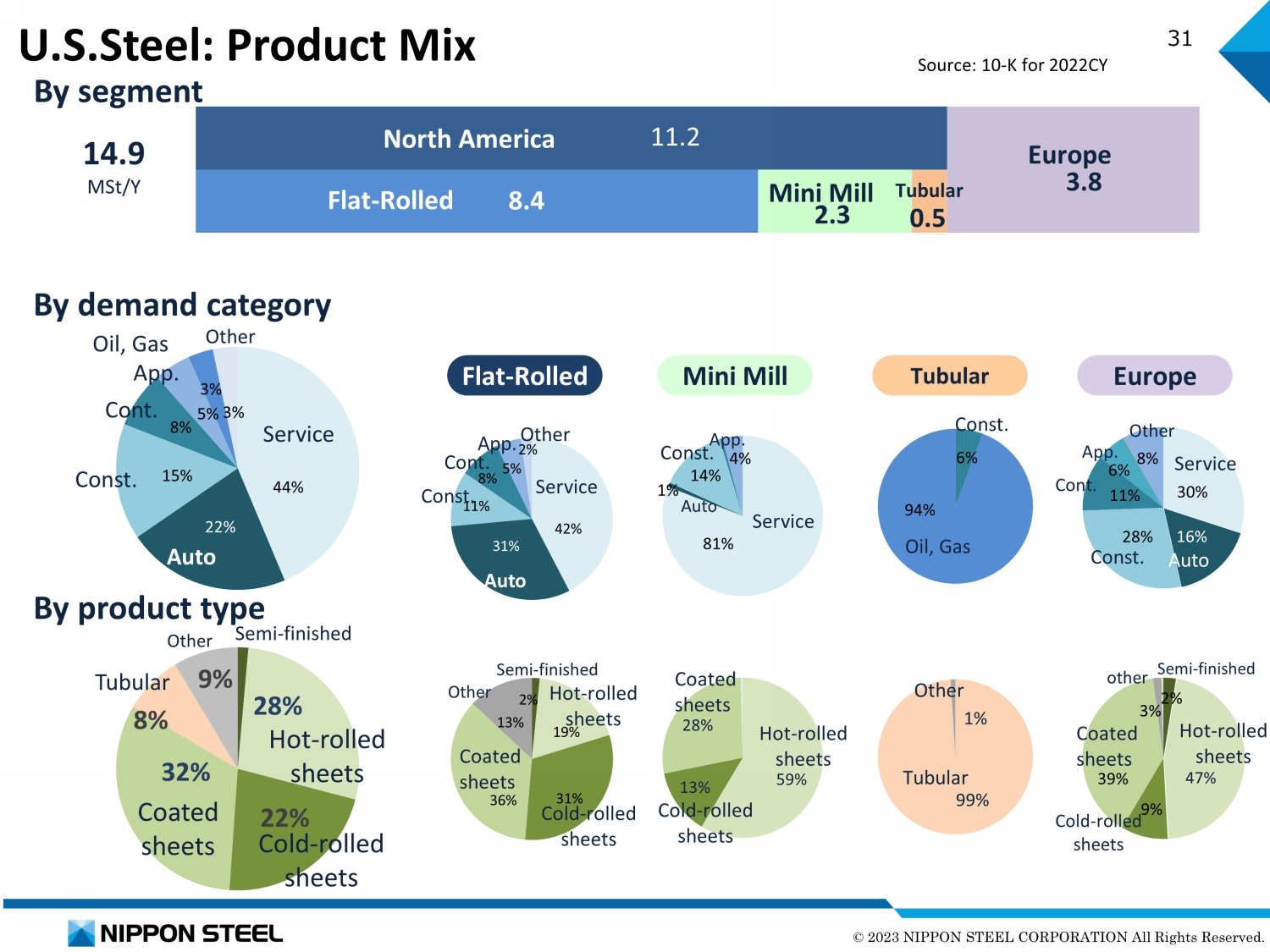

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 31 U.S.Steel : Product Mix 42% 31% 11% 8% 5% 2% Service Auto Const. App. Other Cont. Flat - Rolled Mini Mill Tubular Europe 81% 1% 14% 4% Service Auto App. Const. 6% 94% Oil, Gas Const. 30% 16% 28% 11% 6% 8% Service Auto Other Cont. Const. App. 44% 22% 15% 8% 5% 3% 3% Service Auto Const. Oil, Gas Other Cont. App. 8.4 2.3 0.5 11.2 3.8 Flat - Rolled North America Mini Mill Europe Tubular 14.9 MSt /Y By demand category By product type 2% 19% 31% 36% 13% Hot - rolled sheets Semi - finished Cold - rolled sheets Coated sheets Other 59% 13% 28% Hot - rolled sheets Cold - rolled sheets Coated sheets 99% 1% Tubular Other 3% 47% 9% 39% 2% Hot - rolled sheets Semi - finished Cold - rolled sheets Coated sheets other 28% 22% 32% 8% 9% Hot - rolled sheets Semi - finished Tubular Cold - rolled sheets Coated sheets Other By segment Source: 10 - K for 2022CY

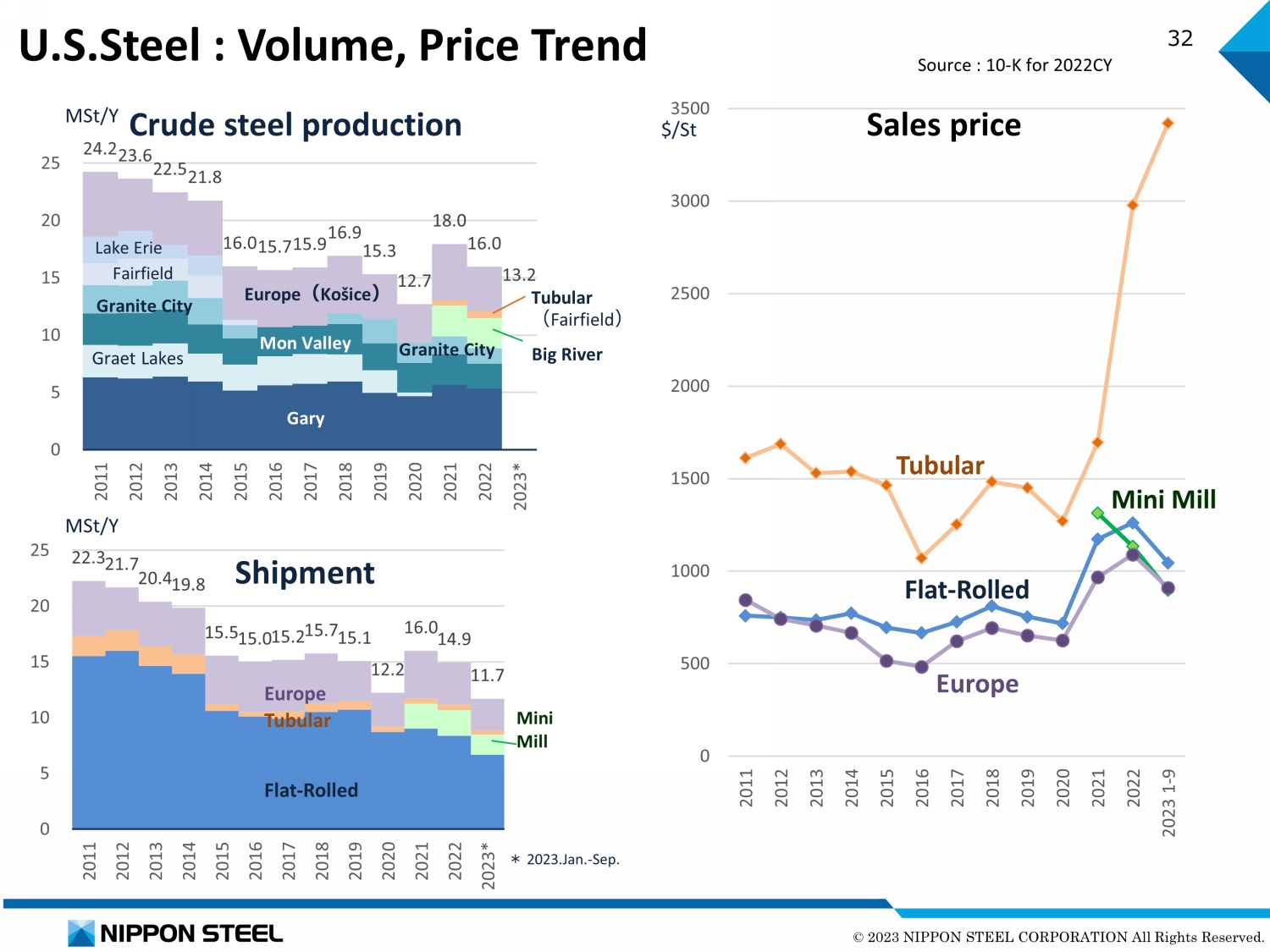

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 32 U.S.Steel : Volume, Price Trend 24.2 23.6 22.5 21.8 16.0 15.7 15.9 16.9 15.3 12.7 18.0 16.0 13.2 0 5 10 15 20 25 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021 2022 2023* Mon Valley Fairfield Europe ( Košice ) Graet Lakes Gary Lake Erie Tubular ( Fairfield ) Granite City Big River Granite City MSt /Y Crude steel production 22.3 21.7 20.4 19.8 15.5 15.0 15.2 15.7 15.1 12.2 16.0 14.9 11.7 0 5 10 15 20 25 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021 2022 2023* Flat - Rolled Mini Mill Tubular Europe 0 500 1000 1500 2000 2500 3000 3500 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021 2022 2023 1-9 Flat - Rolled Mini Mill Tubular Europe $/St Shipment Sales price * 2023.Jan. - Sep. Source : 10 - K for 2022CY MSt /Y

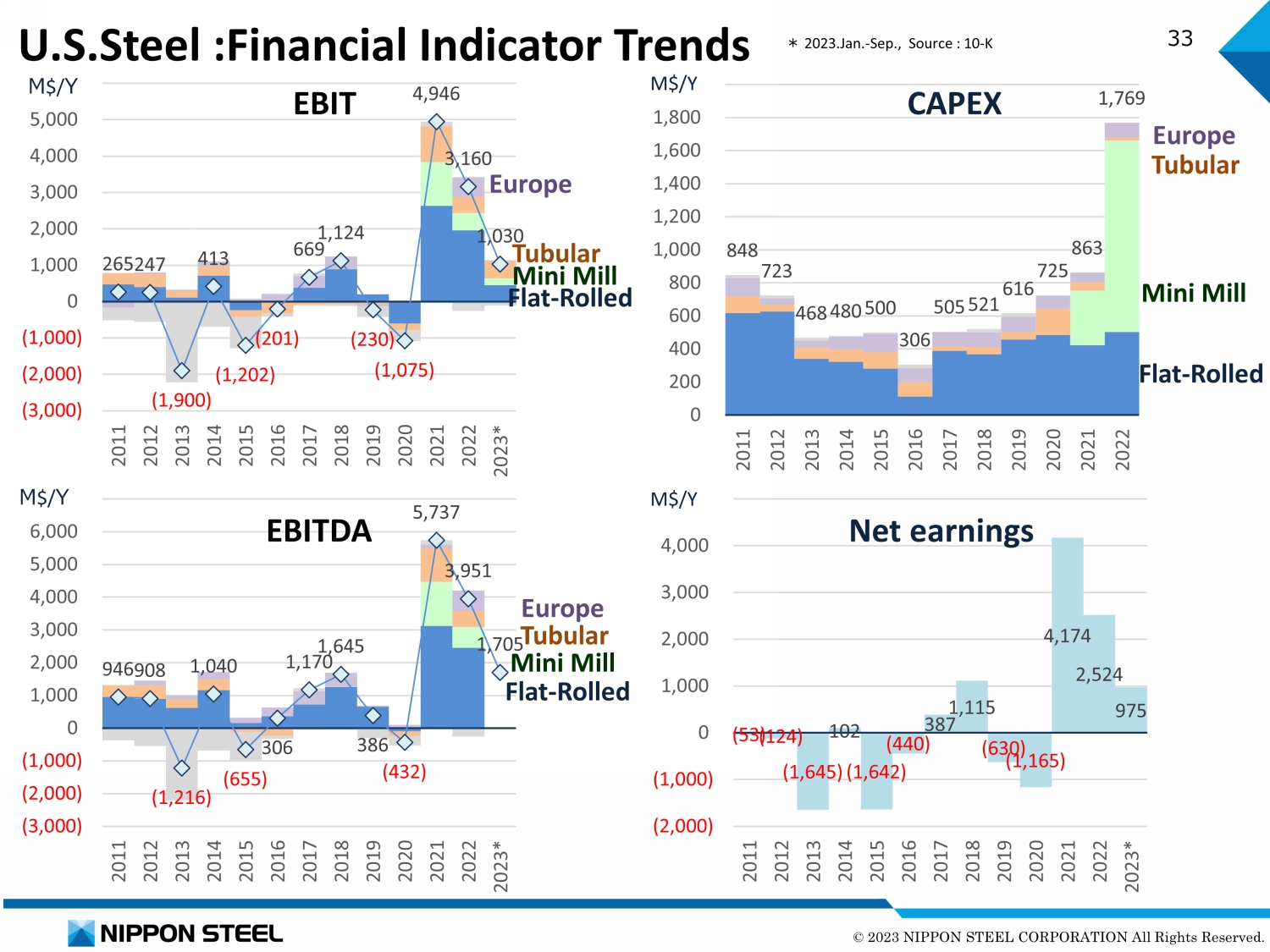

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 33 U.S.Steel :Financial Indicator Trends 265 247 (1,900) 413 (1,202) (201) 669 1,124 (230) (1,075) 4,946 3,160 1,030 (3,000) (2,000) (1,000) 0 1,000 2,000 3,000 4,000 5,000 6,000 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021 2022 2023* M $/ Y Flat - Rolled Mini Mill Tubular Europe EBIT 946 908 (1,216) 1,040 (655) 306 1,170 1,645 386 (432) 5,737 3,951 1,705 (3,000) (2,000) (1,000) 0 1,000 2,000 3,000 4,000 5,000 6,000 7,000 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021 2022 2023* M $/ Y Flat - Rolled Mini Mill Tubular Europe EBITDA 848 723 468 480 500 306 505 521 616 725 863 1,769 0 200 400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021 2022 M$/Y Flat - Rolled Mini Mill Tubular Europe CAPEX (53) (124) (1,645) 102 (1,642) (440) 387 1,115 (630) (1,165) 4,174 2,524 975 (2,000) (1,000) 0 1,000 2,000 3,000 4,000 5,000 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021 2022 2023* M$/Y Net earnings * 2023.Jan. - Sep., Source : 10 - K

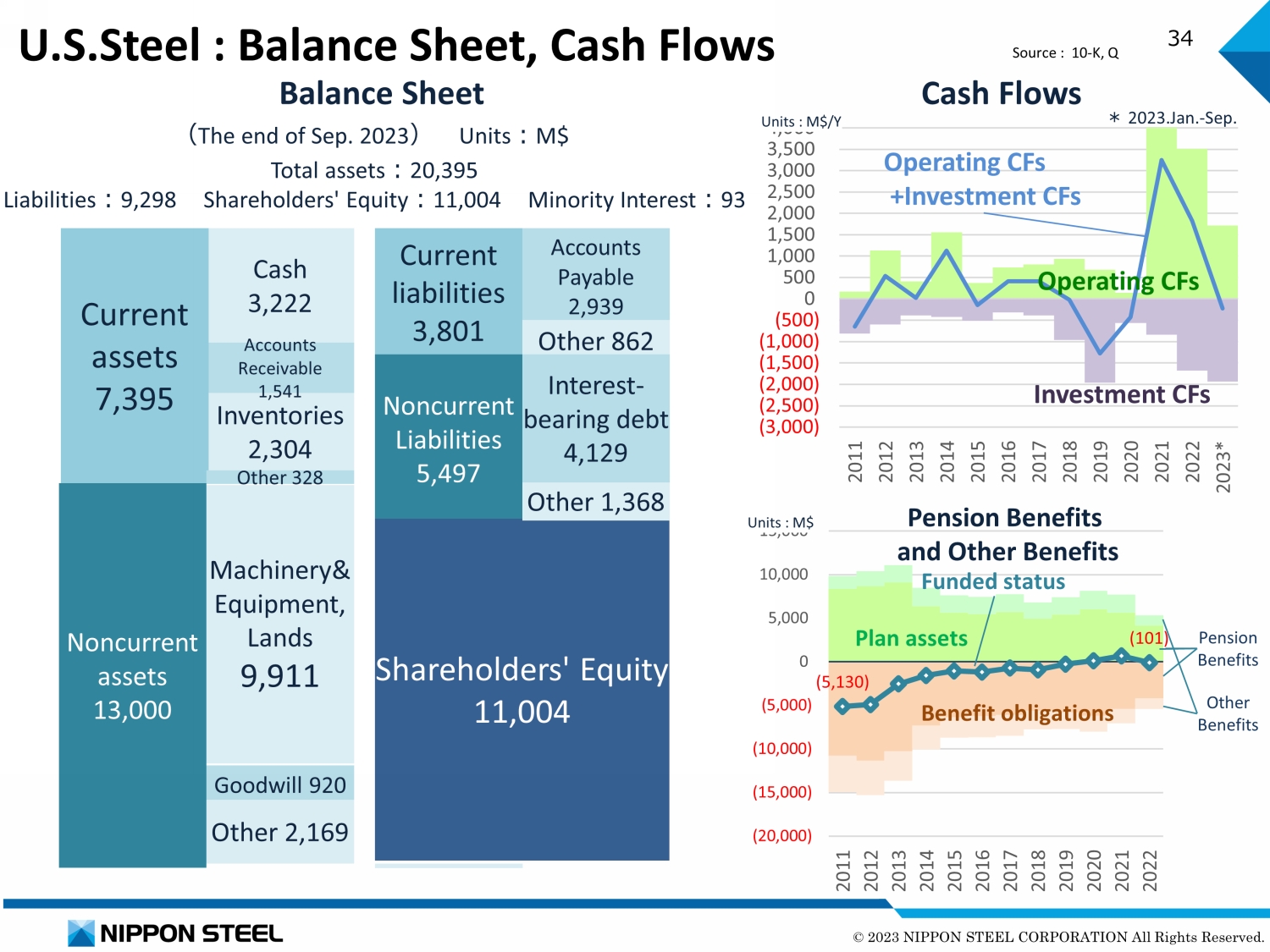

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 34 (5,130) (101) (20,000) (15,000) (10,000) (5,000) 0 5,000 10,000 15,000 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021 2022 Units : M$ Benefit obligations Funded status Pension Benefits Plan assets Other Benefits U.S.Steel : Balance Sheet, Cash Flows ( The end of Sep. 2023 ) Units : M$ Cash 3,222 Inventories 2,304 Accounts Receivable 1,541 Machinery& Equipment , Lands 9,911 Current assets 7,395 Noncurrent assets 13,000 Other 328 Goodwill 920 Other 2,169 Current liabilities 3,801 Noncurrent Liabilities 5,497 Shareholders' Equity 11,004 Accounts Payable 2,939 Other 862 Other 1,368 Interest - bearing debt 4,129 Total assets : 20,395 Liabilities : 9,298 Shareholders' Equity : 11,004 Minority Interest : 93 Cash Flows Balance Sheet (3,000) (2,500) (2,000) (1,500) (1,000) (500) 0 500 1,000 1,500 2,000 2,500 3,000 3,500 4,000 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021 2022 2023* Operating CFs Investment CFs Units : M$/Y Operating CFs +Investment CFs * 2023.Jan. - Sep. Pension Benefits and Other Benefits Source : 10 - K , Q

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 35 This presentation does not constitute an offer or invitation to subscribe for or purchase any securities and nothing containe d h erein shall form the basis of any contract or commitment whatsoever. This presentation is being furnished to you solely for your information and may not be re pro duced or redistributed to any other person. No warranty is given as to the accuracy or completeness of the information contained herein. Investors and pr osp ective investors in securities of any issuer mentioned herein are required to make their own independent investigation and appraisal of the business and financial con dition of such company and the nature of the securities. Any decision to purchase securities in the context of a proposed offering, if any, should be made sol ely on the basis of information contained in an offering circular published in relation to such an offering. By participating in this presentation, you agre e t o be bound by the foregoing limitations. This presentation contains statements that constitute forward looking statements. These statements appear in a number of pla ces in this presentation and include statements regarding the intent, belief or current expectations of Nippon Steel Corp. or its officers with respect to its fin anc ial condition and results of operations, including, without limitation, future loan loss provisions and financial support to certain borrowers. Such forward looking sta tements are not guarantees of future performance and involve risks and uncertainties, and actual results may differ from those in such forward looking statements as a result of various factors. The information contained in this presentation, is subject to change, including but not limited, to change of economic conditions , f inancial market conditions, and change of legislation / government directives. Any statements in this document. other than those of historical facts, are forward - looking statements about future performance o f Nippon Steel Corporation and its group companies, which are based on management’s assumptions and beliefs in light of information currently available, and inv olv e risks and uncertainties. Actual results may differ materially from these forecasts.

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 36 Additional Information and Where to Find It This presentation relates to the proposed transaction between the United States Steel Corporation (“ U. S. Steel ”) and NSC. In connection with the proposed transaction, U. S. Steel will file relevant materials with the United States Securities and Exch ang e Commission (“ SEC ”), including U. S. Steel’s proxy statement on Schedule 14A (the “ Proxy Statement ”). The information in the preliminary Proxy Statement will not be complete and may be changed. The definitive Proxy Statement will be delivered to stoc kho lders of U. S. Steel. U. S. Steel may also file other documents with the SEC regarding the proposed transaction. This presentation is not a substitute for the Proxy Statement or for any other document that may be filed with the SEC in connection with the proposed transaction. The proposed transaction will be submitted to U. S. Steel’s stockholders for their consideration. BEFORE MAKING A NY VOTING DECISION, U. S. STEEL’S STOCKHOLDERS ARE URGED TO READ ALL RELEVANT DOCUMENTS FILED OR TO BE FILED WITH THE SEC, INCLUDING THE PROXY STATEMENT, AS WELL AS ANY AMENDMENTS OR SUPPLEMENTS TO THOSE DOCUMENTS, CAREFULLY AND IN THEIR ENTIRETY IF AND WHEN THEY BECOME AVAILABLE BECAUSE THEY WILL CONTAIN IMPORTANT INFORMATION ABOUT U. S. STEEL, NSC AND THE PROPOSED TRANSACTION. U. S. Steel’s stockholders will be able to obtain free copies of the preliminary Proxy Statement and the definitive Proxy Sta tem ent (in each case, if and when available), as well as other documents containing important information about U. S. Steel, NSC and the proposed transaction once such documents are filed with the SEC, without charge, at the SEC’s website (www.sec.gov). Copies of the Proxy Statement and the other documents filed with the SEC by U. S. Steel can also be obtained, without charge, by directing a r equest to United States Steel Corporation, 600 Grant Street, Pittsburgh, Pennsylvania 15219, Attention: Corporate Secretary; telepho ne 412 - 433 - 1121, or from U. S. Steel’s website www.ussteel.com.

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 37 Participants in the Solicitation NSC, U. S. Steel and their directors, and certain of their executive officers and employees may be deemed to be participants in the solicitation of proxies from U. S. Steel’s stockholders in respect of the proposed transaction. Information regarding the directors and executive officers o f U . S. Steel who may, under the rules of the SEC, be deemed participants in the solicitation of U. S. Steel’s stockholders in connection with the proposed transact ion , including a description of their direct or indirect interests, by security holdings or otherwise, will be set forth in the Proxy Statement when it is filed wi th the SEC. Information about these persons is included in each company’s annual proxy statement and in other documents subsequently filed with the SEC, and will be included in the Proxy Statement when filed. Free copies of the Proxy Statement and such other materials may be obtained as described in the preced ing paragraph.

© 2023 NIPPON STEEL CORPORATION All Rights Reserved. 38 Forward - Looking Statements This presentation contains information regarding U. S. Steel and NSC that may constitute “forward - looking statements,” as that t erm is defined under the Private Securities Litigation Reform Act of 1995 and other securities laws, that are subject to risks and uncertainties. We intend the forward - looking statements to be covered by t he safe harbor provisions for forward - looking statements in those sections. Generally, we have identified such forward - looking statements by using the words “believe,” “expect,” “intend,” “estimate,” “ant icipate,” “project,” “target,” “forecast,” “aim,” “should,” “plan,” “goal,” “future,” “will,” “may” and similar expressions or by using future dates in connection with any discussion of, among other th ing s, statements expressing general views about future operating or financial results, operating or financial performance, trends, events or developments that we expect or anticipate will occur in the fu tur e, anticipated cost savings, potential capital and operational cash improvements and changes in the global economic environment, as well as statements regarding the proposed transaction, including the timin g o f the completion of the transaction. However, the absence of these words or similar expressions does not mean that a statement is not forward - looking. Forward - looking statements include all statements tha t are not historical facts, but instead represent only U. S. Steel’s beliefs regarding future goals, plans and expectations about our prospects for the future and other events, many of which, by their n atu re, are inherently uncertain and outside of U. S. Steel’s or NSC’s control. It is possible that U. S. Steel’s or NSC’s actual results and financial condition may differ, possibly materially, from the anticip ate d results and financial condition indicated in these forward - looking statements. Management of U. S. Steel or NSC, as applicable, believes that these forward - looking statements are reasonable as of the time ma de. However, caution should be taken not to place undue reliance on any such forward - looking statements because such statements speak only as of the date when made. In addition, forward - looking statem ents are subject to certain risks and uncertainties that could cause actual results to differ materially from U. S. Steel's or NSC’s historical experience and our present expectations or projections. R isk s and uncertainties include without limitation: the ability of the parties to consummate the proposed transaction on a timely basis or at all; the timing, receipt and terms and conditions of any required go vernmental and regulatory approvals of the proposed transaction that could cause the parties to terminate the definitive agreement and plan of merger relating to the proposed transaction (the “Merger Agr eement”); the occurrence of any event, change or other circumstances that could give rise to the termination of the Merger Agreement; the possibility that U. S. Steel’s stockholders may not approve t he proposed transaction; the risks and uncertainties related to securing the necessary stockholder approval; the risk that the parties to the Merger Agreement may not be able to satisfy the conditions t o t he proposed transaction in a timely manner or at all; risks related to disruption of management time from ongoing business operations due to the proposed transaction; certain restrictions during the pendency of the proposed transaction that may impact U. S. Steel’s ability to pursue certain business opportunities or strategic transactions; the risk that any announcements relating to the proposed transactio n c ould have adverse effects on the market price of U. S. Steel’s common stock or NSC’s common stock or American Depositary Receipts; the risk of any unexpected costs or expenses resulting from the proposed tra nsaction; the risk of any litigation relating to the proposed transaction; and the risk that the proposed transaction and its announcement could have an adverse effect on the ability of U. S. Steel or NSC to retain customers and retain and hire key personnel and maintain relationships with customers, suppliers, employees, stockholders and other business relationships and on its operating results and business ge nerally; and the risk the pending proposed transaction could distract management of U. S. Steel. U. S. Steel directs readers to its Form 10 - K for the year ended December 31, 2022 and Quarterly Repo rt on Form 10 - Q for the quarter ended September 30, 2023, and the other documents it files with the SEC for other risks associated with U. S. Steel’s future performance. These documents contain an d i dentify important factors that could cause actual results to differ materially from those contained in the forward - looking statements. Risks related to NSC’s forward - looking statements include, but are not limit ed to, changes in regional and global macroeconomic conditions, particularly in Japan, China and the United States; excess capacity and oversupply in the steel industry; unfair trade and pricing practices in regional markets; the possibility of low steel prices or excess iron ore supply; the possibility of significant increases in market prices of essential raw materials; the possibility of depreciation of the valu e o f the Japanese yen against the U.S. dollar and other major foreign currencies; the loss of market share to substitute materials; NSC’s ability to reduce costs and improve operating efficiency; the possibility of n ot completing planned alliances, acquisitions or investments, or such alliances, acquisitions or investments not having the anticipated results; natural disasters and accidents or unpredictable events which ma y disrupt NSC’s supply chain as well as other events that may negatively impact NSC’s business activities; risks relating to CO2 emissions and NSC’s challenge for carbon neutrality; the economic, political , s ocial and legal uncertainty of doing business in emerging economies; the possibility of incurring expenses resulting from any defects in our products or incurring additional costs and reputational harm due to p rod uct defects of other steel manufacturers; the possibility that we may be unable to protect our intellectual property rights or face intellectual property infringement claims by third parties; changes in la ws and regulations of countries where we operate, including trade laws and tariffs, as well a tax, environmental, health and safety laws; and the possibility of damage to our reputation and business due to data b rea ches and data theft. All information in this presentation is as of the date above. Neither U. S. Steel nor NSC undertakes any duty to update any forward - looking statement to conform the statement to actual resul ts or changes in U. S. Steel’s or NSC’s expectations whether as a result of new information, future events or otherwise, except as required by law.